The Massage Stroke

This isn’t a real step in the 4-stroke cycle; this is the part where you have a full understanding of what’s happening in your engine, and now you have a desire to make The Bang stroke produce more power in your engine. When attempting to modify your engine or replace existing parts in the quest for more power, you must remember one rule: you can never get something for nothing. The OE factory engineering team usually does a remarkable job of designing an engine that can meet the myriad of demands placed on a modern powerplant. Keep in mind, most of the engineers that work for the manufacturers are not dummies; they just have to play in a game with a lot of rules related to emissions, cost and other things they can’t control.

The design goals of a stock engine are not solely to make the maximum amount of power possible. Stock engines must; run smoothly and quietly, produce power over a wide RPM range, last a long time, obtain maximum fuel economy, run on fuel ranging from 85 to 94 octane without blowing up, make as little pollution as possible and most of all, must be cheap to mass produce. That’s a lot of musts, and a lot of compromises that the factory engineer has to make.

Since you, the enthusiast driver, are willing to tweak some of these compromises to get the speed to feed your addiction, you have options that reduce or eliminate these restrictions. But, since you can’t get something for nothing, you have to remember that increasing power will come at the expense of lowering fuel economy, raising emissions, having a narrower powerband and perhaps a shortening of your engine’s expected lifespan.

Ratio Hand If You’re Sure

Compression ratio is a very important term that gets thrown around a lot when people talk about engines. The compression ratio is a ratio of the volume of a cylinder when the piston is at the bottom of its stroke (BDC) to the volume of the cylinder when the piston is at the top of its stroke (TDC). The compression ratio is described as a numeric ratio and is affected by a number of factors: the volume of the cylinder head’s combustion chamber, the piston top design (domed, dished, flat), the head gasket thickness and the deck height of the block. Higher compression ratios make the expansion ratio of the combusted gasses greater, meaning more energy is impinged on the piston top, pushing it down harder and making more power. Increasing the compression ratio improves the thermal efficiency of an engine; this is the primary reason why higher compression increases power. Improved thermal efficiency results in improved fuel economy by getting more power from the same amount of fuel. Fuel economy is also increased by reducing the combustion chamber surface area and volume needed to fill the combustion chamber, resulting in less wasted combustion heat and more expansion being used to drive the piston down.

A domed piston like this one will increase the compression ratio of an engine.

A domed piston like this one will increase the compression ratio of an engine.

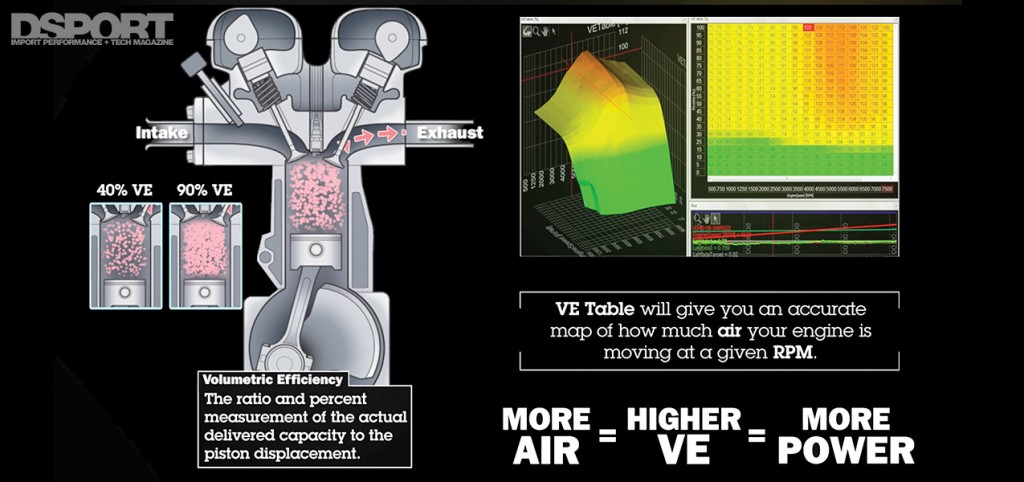

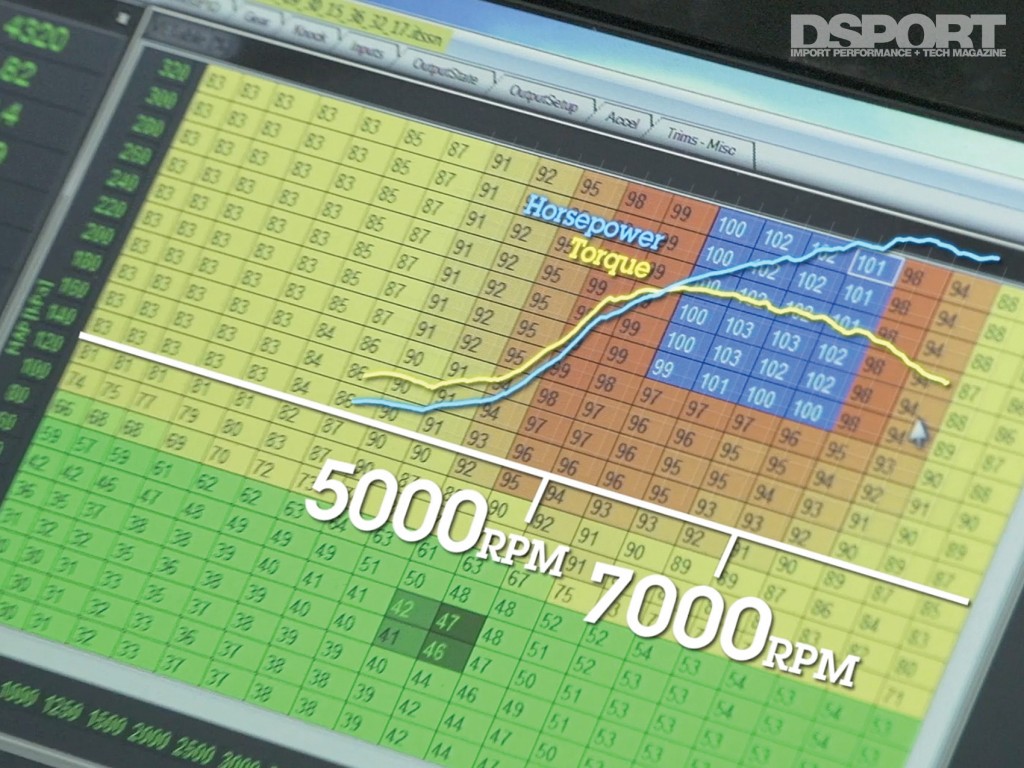

Volumetric Efficiency

Volumetric efficiency (VE) in short is the measurement of how well the engine can move the air-fuel mixture into and out of the engine’s cylinders. VE is the percentage of charge mixture that dynamically enters the cylinder during the intake stroke compared to the actual displacement of the cylinder. The higher this percentage the higher the VE, meaning more air and fuel will be sucked into an engine to make more power.

You might hear the term dynamic compression ratio thrown around a lot. This term is a misnomer as there is no such thing as a dynamic compression ratio except in an old Saab or in research engines where the compression ratio can be changed on the fly. The engine’s dynamic cylinder pressure can be affected by many things, but this is not the compression ratio as we know it, which is a fixed mechanical ratio that doesn’t change.

There are some disadvantages to raising an engine’s compression. A higher octane gas may be required to avoid detonation. Increasing compression also means more heat must be dissipated to avoid engine damage and detonation.

Turbo and supercharged engines usually have lower compression ratios, in the range of 7.0-9.5:1. The compression ratio is lower on these engines because the turbo or supercharger packs a lot more air-fuel mixture into the cylinders. This raises cylinder pressure considerably and thus the compression ratio must be lower to avoid excessive cylinder pressures and detonation.

VE-based tuning systems such as AEM’s Infinity allows tuners to swap parts like camshafts, exhausts and turbos without the need to re-tune the engine.

A/F Ones

The air/fuel ratio is the ratio of air-to-fuel expressed as a ratio. Fuel alone will not burn. It must be combined with oxygen from the air to form a combustible mixture. The perfect chemical balance of air-to-fuel ratio by mass is 14.7 to 1 (this is 14.7 parts of air to one part of fuel). At this ratio and under ideal conditions all of the fuel and oxygen will be consumed by combustion. Chemists and engineers call this a stoichiometric ratio.

A modern car’s ECU is programmed to run at 14.7:1 during cruise and light acceleration for low emissions, keeping catalytic converters happy in these common modes of operation (the catalytic converter only works well near this ratio of air and fuel). Although a stoichiometric A/F ratio is optimal for low emissions, engines produce more power at richer A/F-ratios. So, the engine’s ECU is also programmed to go to a richer mixture (less than 14.7:1 A/F) at wide-open throttle for more power. Since most street cars spend only a small amount of time at wide-open throttle they can be tuned for maximum power without hurting the environment as much as greenies claim.

Naturally-aspirated engines usually produce the best power with an A/F ratio near 13.0:1 at wide open throttle, although 12.5:1 is a bit safer because leaner air/fuel ratios (where there are more parts air per part of fuel) burn hotter. If the mixture is too lean and the combustion temperatures increase, the engine can start to overheat and detonate. Since stock engines are engineered to run under a wide range of fuel qualities they tend to run really rich at wide-open throttle. We have seen A/F ratios as rich as 10.5:1 on completely stock naturally-aspirated engines. This is extremely rich!

Supercharged or turbocharged cars can run as rich as 10.0:1. Richer A/F mixtures burn cooler and can help prevent detonation in these higher-pressure engines. However, mixture ratios richer than 10.0:1 can actually contribute to engine damaging detonation in forced-induction engines. This is due to the excess fuel building up in the combustion chamber and increased cylinder pressures to the point where it can detonate or auto-ignite. You can read more about detonation and auto ignition in the FUEL SYSTEM section.

Wideband air/fuel ratio meters like this one allow fine tuning of the fuel tables for maximum power.

Timing Is Everything

Ignition timing is expressed as the number of degrees of crankshaft rotation in advance of TDC when the spark plug is fired. This kicks off the combustion of air and gasoline that pushes the piston down to drive the crank. Since combustion takes a few milliseconds to develop, the engine’s ECU usually commands the spark plug to fire a few degrees of crank rotation before TDC. This way the combustion will be fully underway by the time the piston reaches TDC and will be able to push the piston down with the greatest effect. If the spark plug fired after TDC the piston would already be going back down the bore and the combustion would not be able to give the piston the biggest push, lowering power output. Firing the spark with retarded timing or after TDC, can also cause the engine to overheat by increasing the amount of time that the burning mixture can impinge upon the engine’s internal parts as the piston travels downward. It can also dump a lot of heat out of the exhaust valve, possibly damaging it and other exhaust components.

The number of degrees that the plug fires before TDC is called advance. Generally, the more advanced the spark, the more developed combustion event will be before the piston reaches TDC. This allows for more pressure to be built up and a more powerful push to be put on the piston on its way back down the bore, but it is possible to advance the timing too much. When an engine’s timing is advanced too far, the spark occurs when the piston is still on its rise to TDC. This can result in an explosion or detonation instead of combustion. This must be avoided.

Go Forth And Multiply

You should now have a better understanding of the actual combustion process and some of the terms that you’ll hear when discussing power production and engine building. You can safely and confidently tell that smart-ass tech at the local shop that you don’t need synthetic headlight grease, but that you’d like to discuss different piston options to increase the power output on your all-motor Honda build. Keep reading the rest of these sections to develop more knowledge on how you can put together the ultimate driving package.

Available on 6/15/15

Fuel systems 101: Supplying Enough Fuel for Fun