ACCORDING TO ONE FRIEND, “SHE’S SMART, SEXY AND LOW-MAINTENANCE.” According to another, “She’s evil. She’ll break your heart and your bank account.” Ask a group of performance enthusiasts about their opinion on nitrous-oxide injection and you’re likely to hear two very different stories. Some opinions can easily be dismissed as they come from those that have never been on a date with nitrous oxide. For those that have had a relationship with nitrous oxide injection, you are still likely to hear stories of overwhelming success and catastrophic failure. Fortunately, DSPORT is here to set the record straight.

Text by Aidan Spraic // Photos by Jun Chen

DSPORT Issue #134

The Success Stories

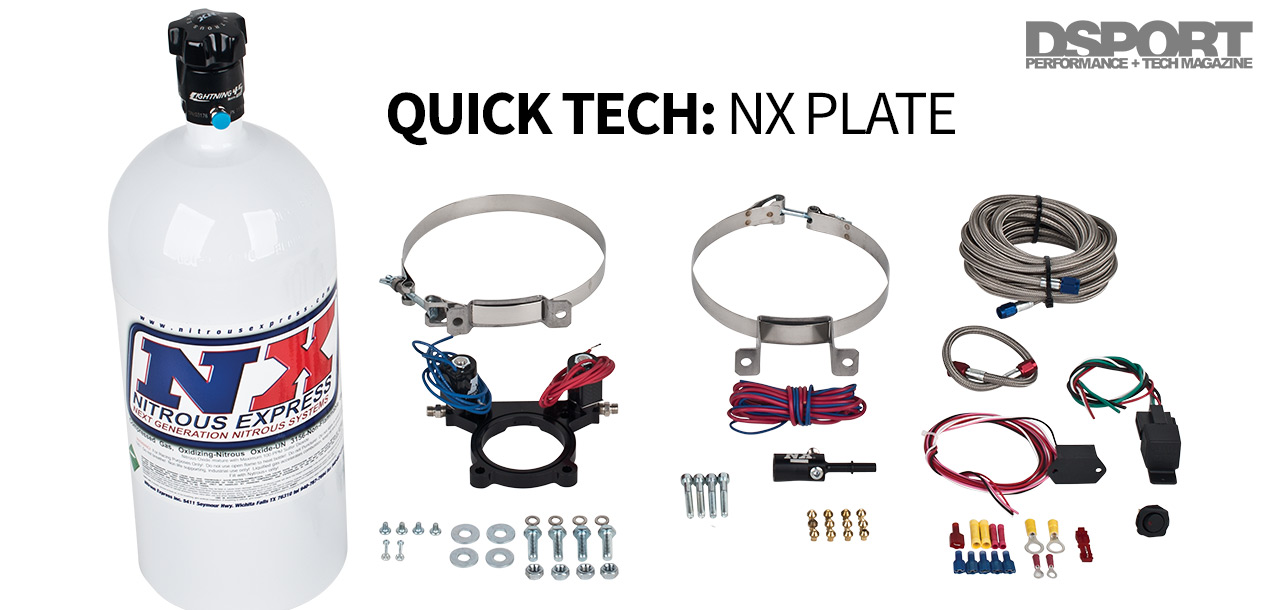

The nitrous-oxide plate enables a much cleaner installation. A properly installed nitrous-oxide injection system will deliver a significant power increase without a major investment of funds. By implementing both electronic and manual safety controls, a well-designed nitrous-oxide injection system should have only one drawback; the bottle can only hold so much nitrous oxide.

The nitrous-oxide plate enables a much cleaner installation.

The nitrous-oxide plate enables a much cleaner installation.

The Horror Stories

If you incorrectly install or setup a nitrous-oxide injection system on an engine, it doesn’t take long for serious engine damage to occur. Engage the system with the engine off, at too low an engine speed or at partial throttle and a nitrous-oxide backfire will likely result. These backfires can decimate throttle bodies and send parts of your throttle body into your engine to do a number on the engine and turbocharger system. Improperly setup the system to inject too much nitrous or too little fuel and you’ve essentially put a blowtorch in your cylinder to cut away at valves and pistons. While serious in nature, all of these nightmares can easily be avoided with a proper install and operation of the nitrous-oxide injection system.

If you incorrectly install or setup a nitrous-oxide injection system on an engine, it doesn’t take long for serious engine damage to occur. Engage the system with the engine off, at too low an engine speed or at partial throttle and a nitrous-oxide backfire will likely result. These backfires can decimate throttle bodies and send parts of your throttle body into your engine to do a number on the engine and turbocharger system. Improperly setup the system to inject too much nitrous or too little fuel and you’ve essentially put a blowtorch in your cylinder to cut away at valves and pistons. While serious in nature, all of these nightmares can easily be avoided with a proper install and operation of the nitrous-oxide injection system.

Frickin’ Really Simple

Nitrous Express has diminished the idiot variable in installation equation with its new FR-S/BRZ Plate System. The nitrous system plate installs in the proper location while ensuring even distribution of nitrous-oxide and fuel through the intake plenum. In addition, an integrated Wide Open Throttle Switch (WOTS) wires directly into the factory TPS signal wire; this prevents incorrect or accidental activation of the system. With these safeguards in place, many potential pitfalls are avoided. Using the proper jetting and activating the system within the proper range of engine RPMs is all that’s needed to keep the system from encountering any conditions that could harm your engine.

Factor of Safety

For our installation, we wanted an idiot-proof solution. Our solution would make sure that the nitrous system couldn’t activate below a set engine speed (RPM), it would automatically turn off at a high RPM mark and would ensure that the system couldn’t activate unless the car was in motion. Typically, an RPM “window” switch is used to meet the first two conditions. These switches allow the user to set a low and high engine speed range that the nitrous system will operate between. In order to also have a safety that prevented the system from activating when the car wasn’t in motion (like at the start line of the drag strip), we used an ARK Design MFD and an MSD RPM switch. The MFD’s “out-put sets” allowed us to set the minimum speed (40-260 KPH) and the minimum engine speed (500-9500 RPM) that the system could be activated. Since 40 KPH is equivalent to 25 MPH, we set this low limit at 40 KPH, preventing system activation below this speed. This allowed for easier launching of the FR-S out of the hole and more consistent engagement of the system. It also allows us to tune the system for slippery track conditions (delaying activation to higher speeds if needed). On the MFD, set the minimum activation RPM at 2,500 RPM. An MSD RPM switch was used to set the high-RPM limit of the system at 7,100 RPM. This ensured that the nitrous system would shut off before the engine hits the rev limiter. Since installation of the MFD normally requires tapping into the factory harness, we opted for a Boomslang ECU expansion harness to avoid that proposition.