10 Best Bearing Practices

1. Never attempt to polish a bearing surface. The overlay maybe only 0.0005” thick and easily damaged.

2. If cleaning of the surface is desired, use acetone on a paper towel and gently wipe. (Check acetone compatibility on coated bearings).

3. Always use a ball anvil insert on a micrometer to measure shell thickness.

4. Never use two bearing shells with more than 0.0005 ”difference in wall thickness.

5. Always put the thicker rod bearing in the upper position (toward the small end of rod).

6. If upper and lower main shells are interchangeable, always put the thicker main bearing in the cap side (not block side).

7. Always measure bearing oil clearance with bearings installed in the block or the rod. Compare these figures to the measurements of the crank’s main and rod pins.

8. Plastigauge is not a substitute for a dial-bore indicator,but it is a good

double-check device.9. Use a small smear of oil under the area where the Plastigauge will be applied.

10. Always save and identify the position of used bearings upon engine disassembly. The used bearings have recorded an entire history of the engine’s performance and will let you know what path to take in the future.

Breaking the Babbitt Habit

How good was Isaac’s Babbitt’s formulation? Considering that today’s babbitt formulation is quite similar to the original, the answer is pretty dang good. The lead-tin alloy with a dash of copper that makes up the overlay varies in composition from manufacturer to manufacturer.

Today, King Race Bearings uses a higher than conventional amount of copper in the overlay alloy for its XP series bearings. The additional copper increases the hardness of the overlay material. Since “harder” materials will generally have a higher tendency to form cracks from fatigue, King Race Bearings treats its XP Series of bearings with a chemical process that increases the surface hardness to resist cracking. This gives the bearings their distinctive black appearance.

Clevite’s TriArmor or K-series bearings use a proprietary moly/graphite applied to the overlay that is infused with PTFE. The PTFE in the coating offers good low-load start-up protection while the moly reduces wear under high-load conditions. The graphite provides great protection when oil flow is marginal.

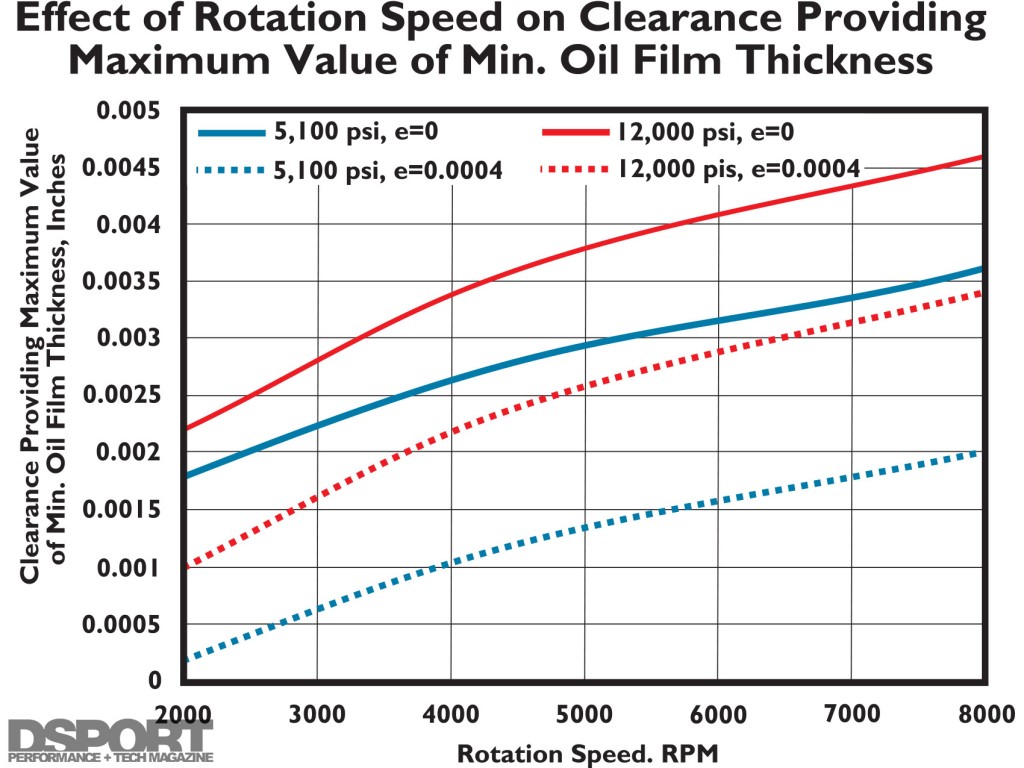

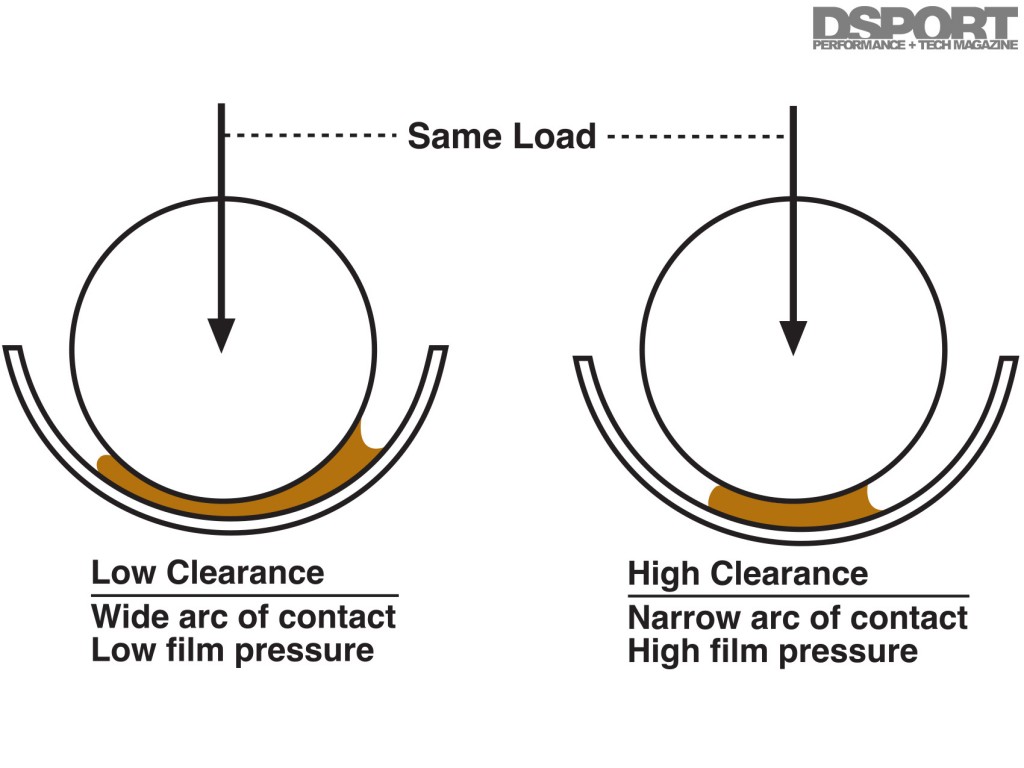

Tight or Loose Clearances

Factory bearing clearance recommendations are great if you plan on building an engine for factory power output. Higher performance clearances generally start on the loose end of factory tolerance and may be even larger. The rule of thumb is a minimum of 0.00075” to 0.0001” thousandth of oil clearance for every inch of pin diameter for the crank plus an additional 0.0005” for safety. If you have a 1.8-inch rod pin, a good starting clearance would be 1.8 x 0.001” or 0.0018” + 0.0005” or 0.0023”.

Tighter Looser Decreases localized pressure Increases localized pressure Spreads load over a larger surface Spreads load over a smaller surface Decreases oil flow through bearing Increases oil flow through bearing Decreased flow increases oil temp Increased flow decreases oil temp Requires high Eccentricity bearing Low-to-Med. Eccentricity bearing OK Requires thinner oils Requires thicker oils Requires better machining Less sensitive to distortions Better for lower engine speeds Required for higher engine speeds

The Bottom Line

If all engines were subject to a higher degree of precision machining and oil filtration eliminated all form of contaminates, the composition of a high-performance engine bearing might be much simpler. There would be no need to conform to housings of non-ideal geometry and there would be no need to embed hard particles as the filter system would remove all. In today’s world, an engine bearing must be both hard and soft at the same time. Hence, the engineering challenge is immense. Fortunately, better materials and better manufacturing allow for today’s high-performance bearings to last for hundreds of thousands of miles.

Hook Ups

Support DSPORT, tell them we sent you

ACL Distribution Inc.

www.aclraceseries.com

King Engine Bearings Inc.

www.kingbearings.com

Mahle

www.askmahleclevite.com