A Closer Look-Valve Timing

While typical explanations of camshafts reduce discussions to lift and duration specs, this is an oversimplification of the overall component. Looking at these two measurements solely tells us only how high a valve is lifted and for how long. What lift and duration fail to tell us is when the valves are opened and closed. If we know that the complete four-stroke cycle contains 720-degrees of crankshaft rotation and the intake stroke (when the piston moves down the cylinder when the intake valve is open) makes up one-fourth of the cycle, we easily deduce that the theoretical duration of the intake cycle is 180 degrees (one-fourth of 720). If we could instantaneously open the intake valve at TDC (the beginning of the intake stroke) and have the intake charge immediately start flowing into the cylinder until the piston was at BDC (the end of the intake stroke, 180 degrees later) where the intake valve would instantaneously slam shut, we might have an engine that would run well with only 180 degrees of intake duration.

Early Intake Valve Opening

In practice, there are many advantages to opening the intake valve early and closing it late. By initiating the opening of the intake valve early, the intake valve has time to get to a lift where appreciable flow will begin. On a well- designed cylinder head teamed with a free-flowing exhaust, the pressure in the cylinder when the valve is opened early may be lower than atmospheric, so the intake charge actually gets sucked in (in practice, the exhaust valve is still open when the intake valve begins to open). The benefits of early intake valve opening are very rpm dependent. At low engine speeds, extremely early intake valve opening may cause exhaust gasses to be sucked into the intake manifold causing erratic idle and other problems. At higher engine speeds, this same amount of early intake valve opening will have no adverse effects since the intake manifold is not operating under a vacuum condition.

Late Intake Valve Closing

Now that we understand why we need to open the intake valve early, let’s take a close look at the closing of the intake valve. The reason we leave the intake valve open past Bottom Dead Center (BDC) is inertia: objects at rest tend to stay at rest, objects (or a mass of air in this case) in motion tend to stay in motion. Since we have an intake charge in motion, we can experience additional filling of the cylinder while the piston dwells (or remains in place) at the bottom of its stroke at BDC. Depending on the rod ratio of the engine, the piston may dwell around BDC for 20 degrees of crank rotation before the piston starts to move up the cylinder. During this time the flowing intake charge continues to fill the cylinder.

If the intake valve closes too late, the piston may pump some of the intake charge out of the cylinder through the intake valve and back into the intake manifold. This reverse flow is obviously undesirable. As you may have guessed, the optimum closing of the intake valve is also very RPM dependent.

Exhaust Valve Open Early

Since we have a good understanding of the intake side of the equation, let’s take a look at the exhaust side. The major difference in dealing with the exhaust side is that the average pressure in the cylinder is probably more than six times the average pressure during the intake cycle. This makes the task of releasing the exhaust gasses easier than trying to get the intake charge into the cylinder.

Exhaust Valve Closing Late

Keeping the exhaust valve open after TDC can also have benefits. If the exhaust valve is kept open after TDC, the intake valve will also be open at the same time. When both intake and exhaust valves are open at the same time, it is termed valve overlap. The ideal amount of overlap depends on rpm. Higher RPMs tolerate more overlap and the intake charge can be drawn into the cylinder due to the draft caused by the exhaust gasses leaving the cylinder. When overlap gets excessive, exhaust gas can make its way into the intake manifold, diluting the intake charge. A diluted intake charge limits power production, so a careful balance must always be struck.

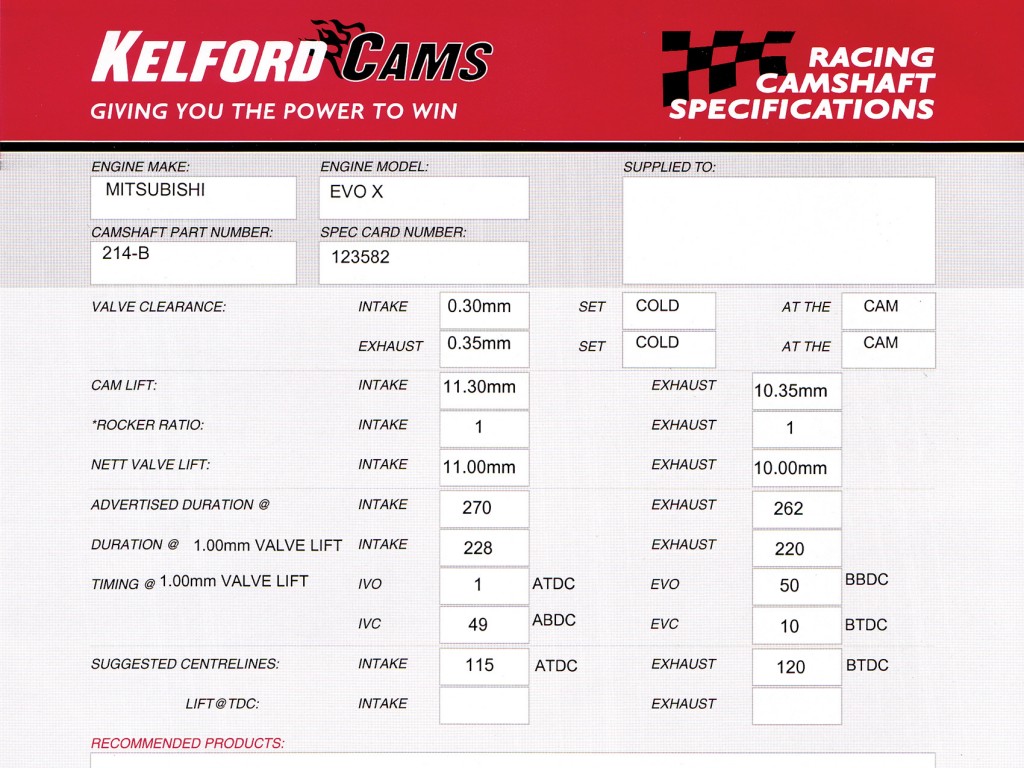

Some aftermarket cam profiles are designed with specific tolerances and settings. Don’t ignore these spec sheets.

Some aftermarket cam profiles are designed with specific tolerances and settings. Don’t ignore these spec sheets.

VTEC: Powerband Optimizer

Many bad explanations of the VTEC advantage have been given in the past. The advantage is simple: VTEC allows the engine to perform as if the cams were switched to a different profile at a set rpm. The low profile can optimize idle, meet emissions and provide good bottom-end torque. The high profile lifts the valves higher and opens the valves longer to improve power at higher rpms.

VTEC does not allow for higher peak power to be made. If a set of non- VTEC cams were ground to match the VTEC high-lobe profile, the same peak power would be made. However, the non-VTEC cam would not have near the performance of the VTEC cam at lower rpms. Driveability, fuel efficiency and idle quality would all suffer.

The end performance result of VTEC technology is an engine that has an incredibly broad powerband.

During the power stroke, the majority of horsepower is generated during the first 90 degrees or first half of this 180 degree cycle. This being the case, opening the exhaust valve early has little effect on killing power. In fact, power is usually increased since the residual pressure is released from the cylinder so the piston doesn’t work as hard to push the remaining gasses out when it begins its upward movement on the exhaust stroke.

The Bottom Line

A camshaft may look simple, but its job is no easy task. Understanding the function, design and limitations of aftermarket cams will allow you to make educated decisions about getting the right cam(s) for your car.

Remember to rely on the experts. The wealth of knowledge that the major cam companies possess is incredible. While it is great to have an understanding of cams, there are enough self-proclaimed engineers in the world. Nine times out of ten, the specialist at the cam company will know more than you (that’s his or her job). The value of your performance education is identifying the one out of ten instances that you may encounter.

As always, remember to consider that the camshaft(s) are just one element of the performance combination. All of the parts in the combination need to work together to produce the maximum in power and reliability. Camshafts will only do their job effectively when complemented with the correct valvetrain components. Installation of the camshaft and complementary valvetrain components must also be done correctly. Failure to do so will result in a loss of performance and the potential for component damage.

Why and How to Degree your DOHC Engine

Have you decked your block? Resurfaced your head? Installed an aftermarket crankshaft or camshafts? If you answered “yes” to any of those questions, your camshaft timing may not be what the camshaft manufacturer specified. Improper cam timing can lead to reduced performance, increased fuel consumption and an increased likelihood of detonation.

A Single-Issue

If you have a single overhead camshaft engine, a camshaft that was not degreed-in properly may be causing the valve’s events to happen sooner (advanced) or later (retarded) than originally intended. When all valve events are advanced in respect to crankshaft rotation (piston position), the engine will typical produce some additional horsepower at lower engine speeds. Unfortunately, the engine may also lose performance at higher engine speeds. Conversely, when all valve events are retarded in respect to crankshaft rotation, the engine will typically lose horsepower at lower engine speeds. However, the engine may also gain performance at higher engine speeds.

While it’s never a bad idea to degree the camshaft(s) in any engine build, it’s usually not imperative to degree the camshafts on SOHC (single over-head camshaft) engines. With SOHC engine, the relationship between the intake and exhaust events is fixed (this measurement is termed the lobe separation angle). Hence, an adjustable cam sprocket simply advances or retards all of the valve events while keeping the lobe separation angle constant. This means that a tuning session on a chassis dyno will quickly allow the cam timing to be advanced or retarded to the position that provides the optimum power curve. In most cases, the majority of aftermarket SOHC camshafts will generally deliver the best curve between zero and slightly advanced.

More than Double Trouble

While taking the time to degree the cam on a SOHC engine may be unnecessary if a chassis dyno will be used in the future for tuning the cam sprocket, taking the time to degree the camshafts in DOHC (double over- head camshaft) engines can avoid some serious potential headaches. If there are errors in cam timing on DOHC engines, it’s rare that both the intake and exhaust cam will have the same exact error in the same exact direction (i.e. both intake and exhaust cam are advance two degrees or retarded four degrees). More often, cam timing errors are different between the intake and exhaust cams. One cam may be advanced more than the other; one cam might be retarded more than the other; or one cam might be advanced while the other retarded. These differences result in a change to the lobe separation angle, which establishes the relationship between the timing of intake and exhaust events. Why is that important? Lobe-separation angle changes (even as small as one degree) could be the reason why an engine can or cannot run at 25psi of boost pressure without encountering detonation.

Bottom Line

If you are taking the time to build your DOHC engine, get the tools and take the time to degree in your camshafts. Finding and correcting cam timing issues long before your engine sees its first drop of fuel will likely lead to a longer and happier life for your engine. It’s also likely to keep you from spending hundreds or maybe even thousands of dollars in trying to get your engine to run right.

Click here for the DSPORT Guide to Degreeing your DOHC Engine

Click here for the 201 Guide to Understanding Your Valvetrain