Airflow to Horsepower Relationship

A flow bench is a device that allows one to measure the volumetric airflow through the intake or exhaust port of a cylinder head. You may have heard someone quoting “cfm” numbers about the airflow of their cylinder head. Before you pay too much attention to the numbers, please understand that comparing flow numbers from one flow bench to another is liable to cause more harm than good.

If you are going to compare airflow numbers, compare the before and after numbers from the same flow bench. Furthermore, a flow number from a flow bench is just that, a number. The flow numbers tell part of the story, but not the whole story when it comes to improving the performance of a cylinder head. According to Allan Lockheed, an expert on cylinder heads and performance engines, “Besides my own school of hard knocks, I have been privileged to learn a GREAT DEAL from listening to and contributing to the following special, great experts in performance. Jerry Branch, David Vizard, Kevin Cameron, Dick Phillips, Jimmy Dour and Dave Vaseleniuk and others have found that horsepower does not necessarily, nor always, increase with increased cylinder head airflow numbers. Additionally, horsepower does not always increase with increased valve lift-duration area.” In fact, the size of the ports play a role that can even be more crucial to performance than the flow numbers themselves.

If you are going to compare airflow numbers, compare the before and after numbers from the same flow bench. Furthermore, a flow number from a flow bench is just that, a number. The flow numbers tell part of the story, but not the whole story when it comes to improving the performance of a cylinder head. According to Allan Lockheed, an expert on cylinder heads and performance engines, “Besides my own school of hard knocks, I have been privileged to learn a GREAT DEAL from listening to and contributing to the following special, great experts in performance. Jerry Branch, David Vizard, Kevin Cameron, Dick Phillips, Jimmy Dour and Dave Vaseleniuk and others have found that horsepower does not necessarily, nor always, increase with increased cylinder head airflow numbers. Additionally, horsepower does not always increase with increased valve lift-duration area.” In fact, the size of the ports play a role that can even be more crucial to performance than the flow numbers themselves.  The optimum size for the cylinder head ports depend on engine speed and displacement. Allan goes on to say, “With a flow bench, we truly measure resistance to airflow, which would be better expressed as a drag or resistance to flow. When an intake or exhaust port is close to the optimum size for the engine capacity and RPM range, increased air flow will increase power nearly linearly. A 10-percent increase in airflow would equate to a 10-percent increase in power, if the port is close to the optimum size. However, if the port is too big for the engine size and rpm range, the increase in airflow attained will not show a like increase in performance. You may attain a 10-percent increase in flow on the bench, but see no horsepower gain on the engine if the ports are too big. The reason is that cylinder performance increases as the square of port velocity, but only linearly with increased flow.” As a result, gains made on the flow bench by increasing the size of the port, may result in only minimal or non-existent gains in horsepower production. For example, if a cylinder heads ported were opened up to pick up 10 percent in airflow at the expense of reducing port velocities by five percent, you’ll end up exactly where you started in the power department. If you walk away with nothing else from this article walk away knowing that the velocity of the flow through the cylinder head ports is more critical than the raw flow numbers for the ports. Allan points out that, “Decreasing the size of a port by 4% may lose 4% in flow, but may increase cylinder filling and engine performance by 4% thanks to velocity.” Before you start getting out the Devcon and filling your cylinder heads ports, you must consider that there are always pros and cons to any modification. Allan continues, “The smaller the port, the more work it takes to accelerate the air through it. As a result, smaller ports will inhibit performance if the wet flow and/or ‘twirl’ are not right.”

The optimum size for the cylinder head ports depend on engine speed and displacement. Allan goes on to say, “With a flow bench, we truly measure resistance to airflow, which would be better expressed as a drag or resistance to flow. When an intake or exhaust port is close to the optimum size for the engine capacity and RPM range, increased air flow will increase power nearly linearly. A 10-percent increase in airflow would equate to a 10-percent increase in power, if the port is close to the optimum size. However, if the port is too big for the engine size and rpm range, the increase in airflow attained will not show a like increase in performance. You may attain a 10-percent increase in flow on the bench, but see no horsepower gain on the engine if the ports are too big. The reason is that cylinder performance increases as the square of port velocity, but only linearly with increased flow.” As a result, gains made on the flow bench by increasing the size of the port, may result in only minimal or non-existent gains in horsepower production. For example, if a cylinder heads ported were opened up to pick up 10 percent in airflow at the expense of reducing port velocities by five percent, you’ll end up exactly where you started in the power department. If you walk away with nothing else from this article walk away knowing that the velocity of the flow through the cylinder head ports is more critical than the raw flow numbers for the ports. Allan points out that, “Decreasing the size of a port by 4% may lose 4% in flow, but may increase cylinder filling and engine performance by 4% thanks to velocity.” Before you start getting out the Devcon and filling your cylinder heads ports, you must consider that there are always pros and cons to any modification. Allan continues, “The smaller the port, the more work it takes to accelerate the air through it. As a result, smaller ports will inhibit performance if the wet flow and/or ‘twirl’ are not right.”

Confused? Perhaps you should be as even the experts are learning more and more every day about cylinder heads and flow dynamics. Here’s our advice. Nearly all cylinder heads will respond well to a “pocket porting” and quality valve job. With pocket porting, the area under the valves seats is addressed to eliminate any restrictions. A quality valve job ensures that the airflow is properly directed around the valve and into the cylinder. Doing anything that results in changes to the shape and size of the ports should be evaluated on the dyno. Lockheed noted that he uses software to pick the size of the ports and valves before building or modifying heads. As we mentioned before, flow numbers don’t tell the entire story, the dyno and the evaluation of all of the area under the power curve is the best indicator.

The Number

Wouldn’t it be nice if there was just one number that could be attached to a cylinder head that would let you know how it would perform? “Although one cannot come up with just one number which defines the quality and applicability of a head to a particular application, one of the best indicators of cylinder head quality is the airflow to minimum port area relationship. The smaller the port through which you move the air your engine requires, the lesser the valve lift and the longer the duration of valve activity (gentler valve train) necessary to make power over a wide RPM range,” says Lockheed.

Wouldn’t it be nice if there was just one number that could be attached to a cylinder head that would let you know how it would perform? “Although one cannot come up with just one number which defines the quality and applicability of a head to a particular application, one of the best indicators of cylinder head quality is the airflow to minimum port area relationship. The smaller the port through which you move the air your engine requires, the lesser the valve lift and the longer the duration of valve activity (gentler valve train) necessary to make power over a wide RPM range,” says Lockheed.

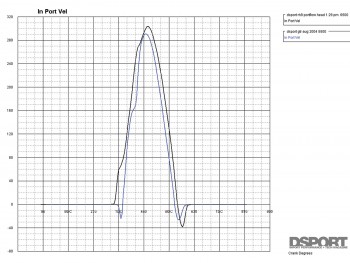

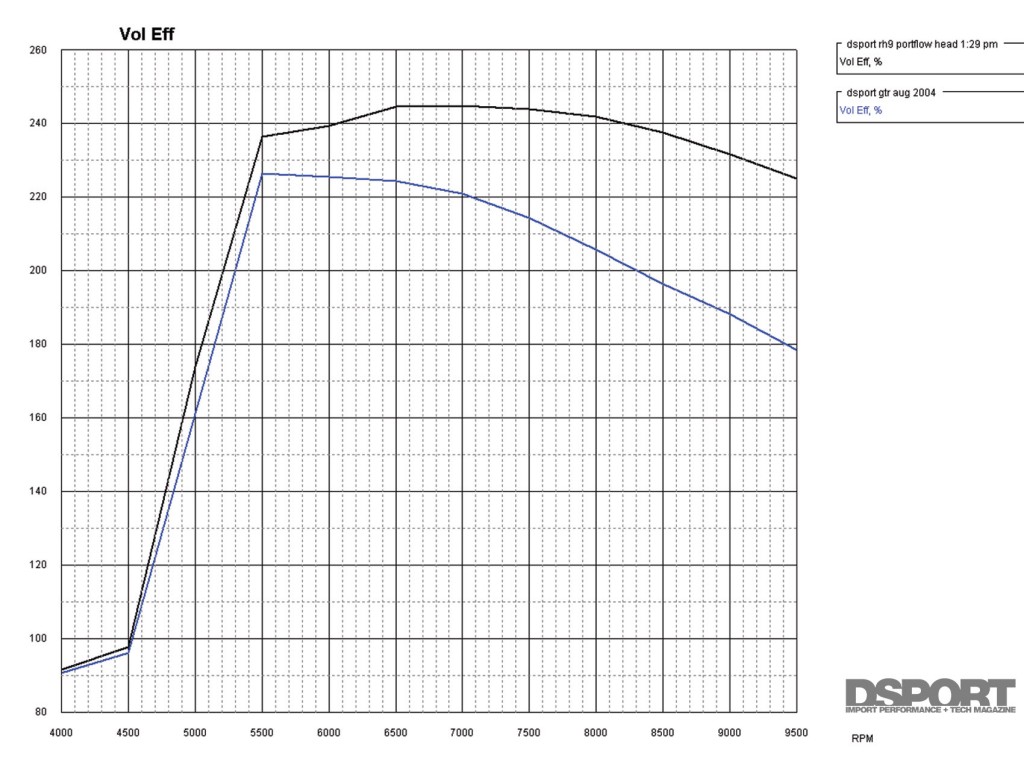

Our Challenge

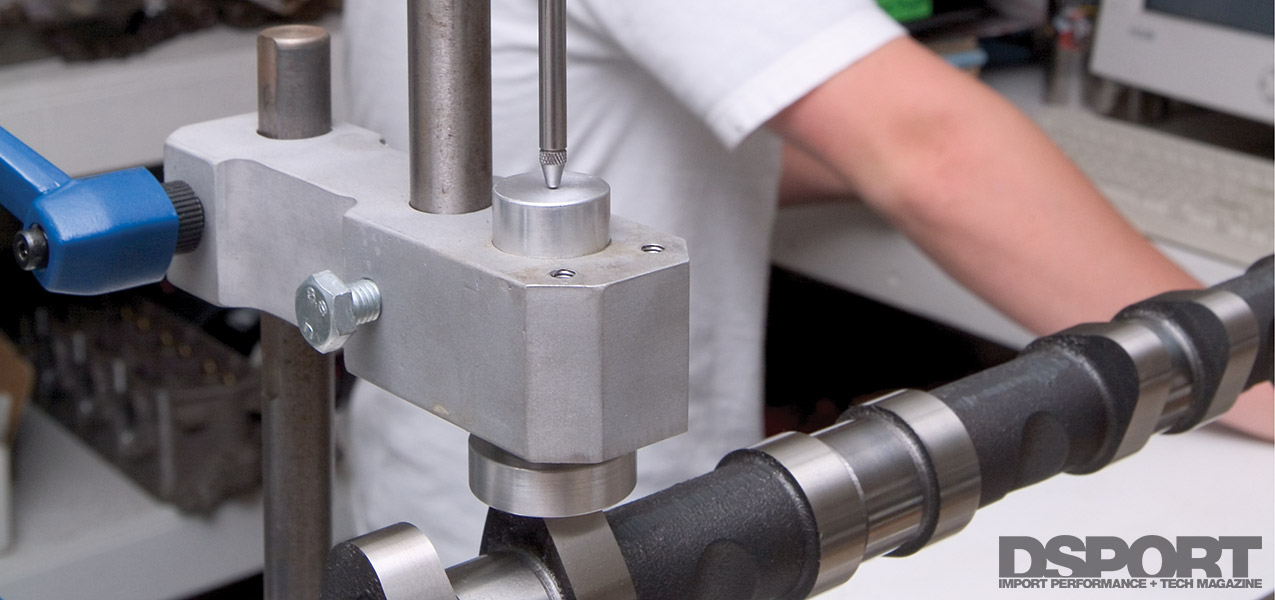

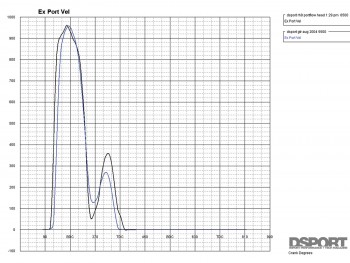

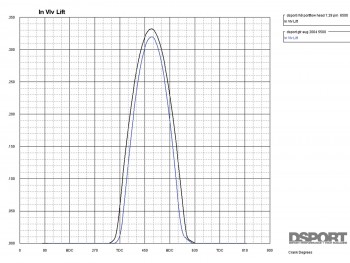

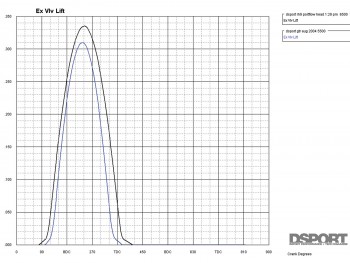

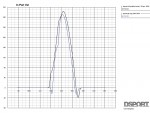

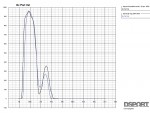

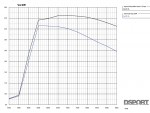

We have been planning on using a ported cylinder head and a pair of performance camshafts on our Project RH9 GT-R for some time. As with any performance modification, we were curious about the amount of performance increase we could expect from these modifications. To get a realistic gauge on the performance increase we contacted Allan Lockheed for his insight on the subject. We also installed Engine Analyzer Pro v3.3 to allow us to plug in some data and see what the computer model would predict. The non-“PRO” version of Engine Analyzer requires fewer inputs, is less expensive and is more suited to the end user than the Pro version. The small investment in this engine modeling software can save you hundreds in proper parts selection in the future. As with any computer model, the output is only going to be as good as the input. Fortunately, Portflow provided all of the cylinder head flow data and Carobu Engineering was kind enough to spin up our cams on their Cam Doctor fixture. This Cam Doctor process recorded the actual cam lift to duration data for the camshafts. Included, you can see the predictions of the computer model. As you would expect, the model predicts that performance gains will be more apparent at the higher rpm levels with the longer duration camshafts and the ported cylinder head. The predicted gains show us producing enough flywheel horsepower to make close to 600 horsepower at the wheels.

Computer Model versus Real World

Our next step is to put the computer model to the test. Within the next two issues, we plan on installing the ported cylinder head along with the camshafts on our GT-R. Then will optimize the fuel and ignition curves for the new setup. Will the real-world numbers match the computer prediction? We hope so. Stay tuned.