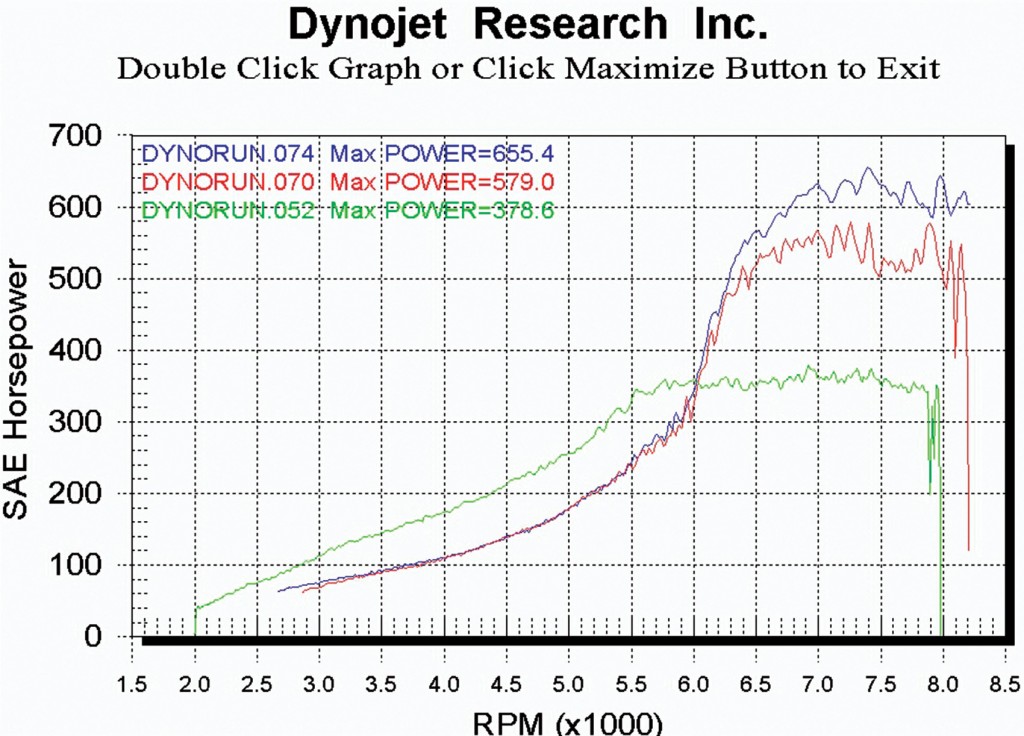

It’s official. We think we accidentally built the most-powerful GT-R in the U.S. At least, it’s the most powerful one that we know about. The previous record holder was the nitrous-fed “Big Bird” from Motorex. Big Bird generated 654 horsepower at the rear wheels.

Text & Photos By Michael Ferrara

So how did our DRAG Sport GT-R better the mark? With Eric “Dai-Lo” Hsu of XS Engineering at the laptop, the A’pex Integration Power FC engine management system was dialed in to help our original RB26 longblock spin the tires to 655 horsepower at 1.58bar (23 psi) of boost pressure. The craziest part of the dyno session was that we could have made more power. Power was only limited by the fact that the fuel delivery system couldn’t supply any additional fuel to the injectors.

–

The Original Plan

Our mantra for this project has been “never buy the same part twice.” In that, we are referring to the all-too-often saga of buying a performance part, only to need a bigger and badder version of that same part in the future. It happens to all of us. You buy a set of high-flow injectors or fuel pump, only to need a bigger set of injectors or fuel pump in the future.

As we mentioned in the first issue, our current combination is a big mismatch. For this issue, the plan was to swap on a set of smaller turbine housings to produce some additional mid-range power. Before swapping on the turbine housings, we decided to address some of the other restrictions in our engine combination.

In the end, we ran out of time before getting to test the smaller turbine housings. However, what we learned in this installment was worth 75 horsepower at the wheels.

–

The Intercooler

Intercoolers help a forced-induction engine combination produce additional power by reducing charge air temperatures into the engine. For every 11 degrees of temperature drop, the charge air will contain enough additional pounds of air to produce one percent more power (as long as the proper amount of fuel is also added to the mix). The importance of an effective intercooler system is obvious.

Intercoolers help a forced-induction engine combination produce additional power by reducing charge air temperatures into the engine. For every 11 degrees of temperature drop, the charge air will contain enough additional pounds of air to produce one percent more power (as long as the proper amount of fuel is also added to the mix). The importance of an effective intercooler system is obvious.

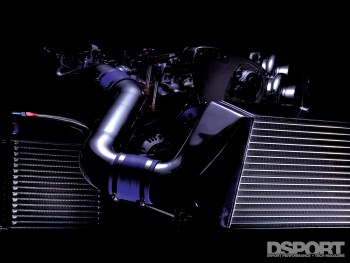

The fact is that we have a set of serious turbochargers and plans to make some serious horsepower. Generating serious horsepower requires high mass air flows and significant boost pressures. High mass air flows and high boost pressures are not the appropriate diet for the OEM intercooler. Thus, we decided to go big.

How big? We went with the biggest that we could find. We found that GReddy Performance Products offers a giant GT-R intercooler with a 75mm inlet and a 100mm outlet. This 100mm outlet matches perfectly with the GReddy intake manifold. Since this intake manifold was on our hot list already, we were sold.

How big? We went with the biggest that we could find. We found that GReddy Performance Products offers a giant GT-R intercooler with a 75mm inlet and a 100mm outlet. This 100mm outlet matches perfectly with the GReddy intake manifold. Since this intake manifold was on our hot list already, we were sold.

Can you go too big on an intercooler? The answer will depend on who you ask. Ask some suspension nerd that races in SCCA and he’ll start talking about response and some other crap. Ask a drag racer that believes that SCCA stands for Slow Cars that Can’t Accelerate and you are liable to get a completely different answer. But seriously in our experience, you can’t make an intercooler that is too big that still fits on the vehicle. Whether on the dyno or at the track, we have yet to see a bigger intercooler slow a car down.

The Induction System

Common sense. Sometimes this is in short supply around a project buildup. However, we tried to exercise some common sense with our approach to the intake manifold and throttle body side of the power equation.

Common sense. Sometimes this is in short supply around a project buildup. However, we tried to exercise some common sense with our approach to the intake manifold and throttle body side of the power equation.

The factory induction system features six 45mm throttle bodies. Each body feeds a single cylinder. All six of the throttle bodies are supplied air by the “surge tank.” This surge tank transfers the air coming from the intercooler into the six throttle bodies. In theory, the part throttle performance of the individual throttle body setup should outperform a comparable single throttle body setup. On the flip side, a larger single throttle body setup should allow the engine to produce more peak power. More peak power is produced since the throttle restriction is moved further away from the intake valve and the throttle plate size is larger. Of course, there is a great deal of science behind induction systems and fluid dynamics, flow velocities, Reynolds numbers and computer modeling can crunch a bunch of numbers to explain these trends.

Once again, we looked to Japan for answers. Japanese tuners have taken two approaches with the RB26 induction system. One group has turned to enlarging the throttle plate size on the individual throttle bodies to 48mm. The other group has eliminated the individual throttle bodies completely and instead they position an 85mm (Q45) or 100mm custom throttle body at the front of the surge tank.

Our common sense approach told us to try improving the current system before entertaining the thought of completely reworking the induction system. With that in mind, we delivered our throttle bodies and mounting manifold to Jay Cee Performance in Huntington Beach, California. Jay Cee is no stranger to throttle plate upgrades as they have been modifying 48mm Weber carbs into 51mm Webers for years. Instead of making a custom throttle plate, Jack at Jay Cee used Weber 48mm plates to fit into the bored-out throttle bodies. To match the throttle bodies to the mounting manifold, we also had Jack port the mounting manifold that goes between the throttle bodies and the heads.

Our common sense approach told us to try improving the current system before entertaining the thought of completely reworking the induction system. With that in mind, we delivered our throttle bodies and mounting manifold to Jay Cee Performance in Huntington Beach, California. Jay Cee is no stranger to throttle plate upgrades as they have been modifying 48mm Weber carbs into 51mm Webers for years. Instead of making a custom throttle plate, Jack at Jay Cee used Weber 48mm plates to fit into the bored-out throttle bodies. To match the throttle bodies to the mounting manifold, we also had Jack port the mounting manifold that goes between the throttle bodies and the heads.

Once the mounting manifold and throttle bodies were placed back onto the cylinder head, we installed the GReddy intake manifold/surge tank. A GReddy 100mm upper pipe kit made the connection between the intake manifold and the intercooler.