While you might’ve had the time of your life rocking out at an AC/DC concert, your engine won’t be having the time of its life if its pistons are rocking excessively. While all pistons exhibit some amount of “rock,” modified engines are more likely to have a more significant “rocking” event. Piston rock occurs each time the piston reaches bottom dead center. As the piston skirt exits the bottom of the cylinder bore, the piston tilts one way. On the way up, the piston ends up rocking left to right. The rocking motion disrupts the piston ring’s seals. A disrupted seal could cause uncontrollable oil problems. Do you think your pistons may be rocking? Most likely. Here we will discuss piston rock and its detrimental effects, what engine combinations increase piston rock, and how to reduce this event and keep your piston ring seals happy and efficient.

Text by Bassem Girgis // Photos by Joe Singleton and Line2Line Coatings

DSPORT Issue #232

The abradable powder coating on the piston skirts would wear-in to the shape of the cylinder. This means if your cylinder is not perfectly round, the coating will have the same effect as if you’ve done the expensive machine work to make it round. The result is saving money on torque-plate honing and needing custom pistons once the machine work is done.

Piston Skirt Design

One of the hardest and least exciting aspects of a piston design is the design of the skirt’s cam-and-barrel 3D profiles. A piston experiences various temperatures from all sides. The top part of the piston experiences high temperatures, while the bottom part experiences low temperatures. The cylinder walls transfer the heat, exposing the sides of the piston to different temperatures than top and bottom. This makes them extremely unpredictable in terms of expansion. OEM manufacturers take the approach of designing a perfect piston for an imperfect cylinder, since taking the time to torque-plate each block and create a perfect cylinder is time and cost consuming. However, once a block is refreshed, honed, or bored, the piston is no longer that perfect and all of the measurements go out of the window. The obvious solution would be a new set of pistons with the proper sizing, but if you don’t want to waste perfectly good pistons or you don’t want to spend the money for new ones, a simple coating could suffice.

For extreme cases where there is no time for engine break-in, the coating is applied with more clearance from the start (60-percent instead of 80-percent).

The Problem

Stepping away from the OEM and into built engines, changing the size of the cylinder becomes a very common thing. Whether it’s to repair a cylinder or to go with a slightly bigger bore, making your current pistons work with your new setup could save a lot of money, especially when you’re servicing the block often after race seasons. If each race season you hone your cylinders and make them .0002” bigger, you could find yourself spending too much money replacing perfectly good pistons or with excessive clearance problems. With the excessive clearance, piston rock occurs, which can reduce efficiency and can be extremely damaging.

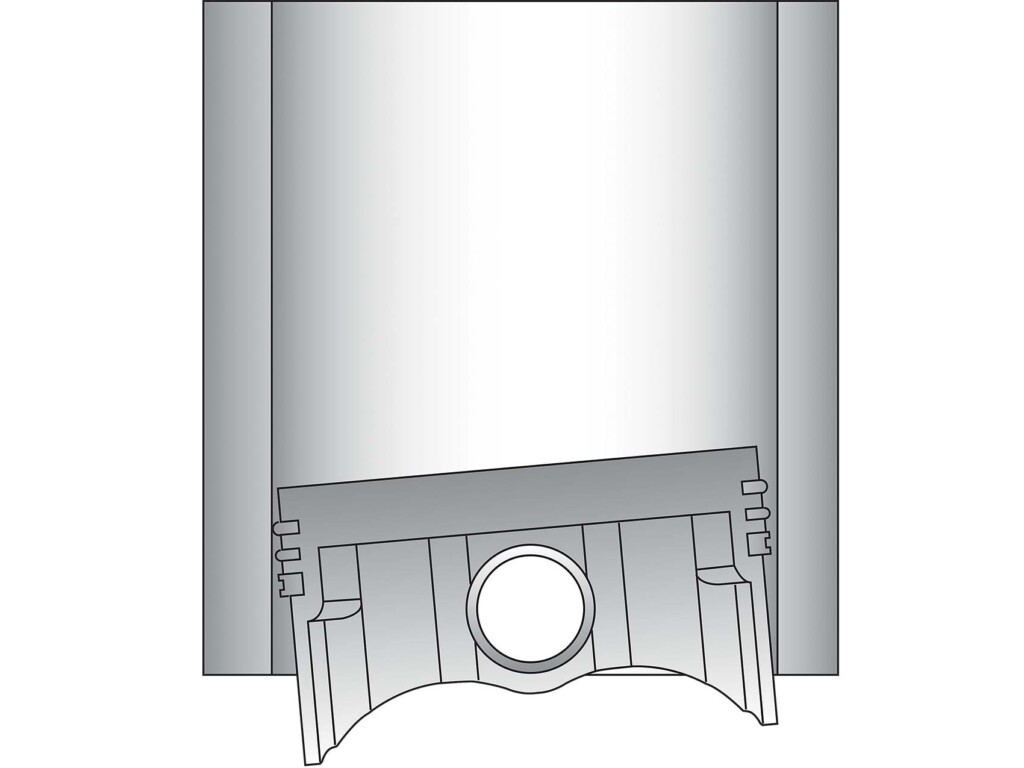

The abradable powder coating is applied to the piston skirts. Once broken-in, micro pores form on the surface that hold the oil in. This increases lubrication to reduce wear.

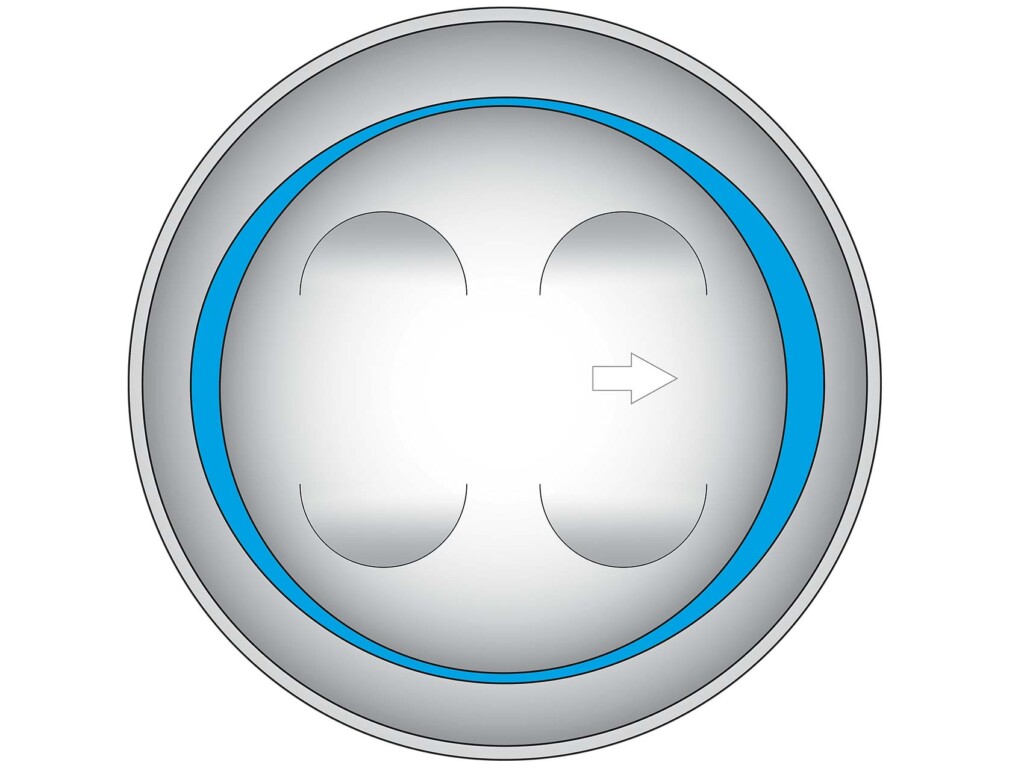

More common in stroker engines, when the piston exits the bottom of the cylinder bore at BDC, the piston rocks side to side. This causes oil problems, piston ring issues, more noise, and a series of other concerns that can cause damage or inefficiency.

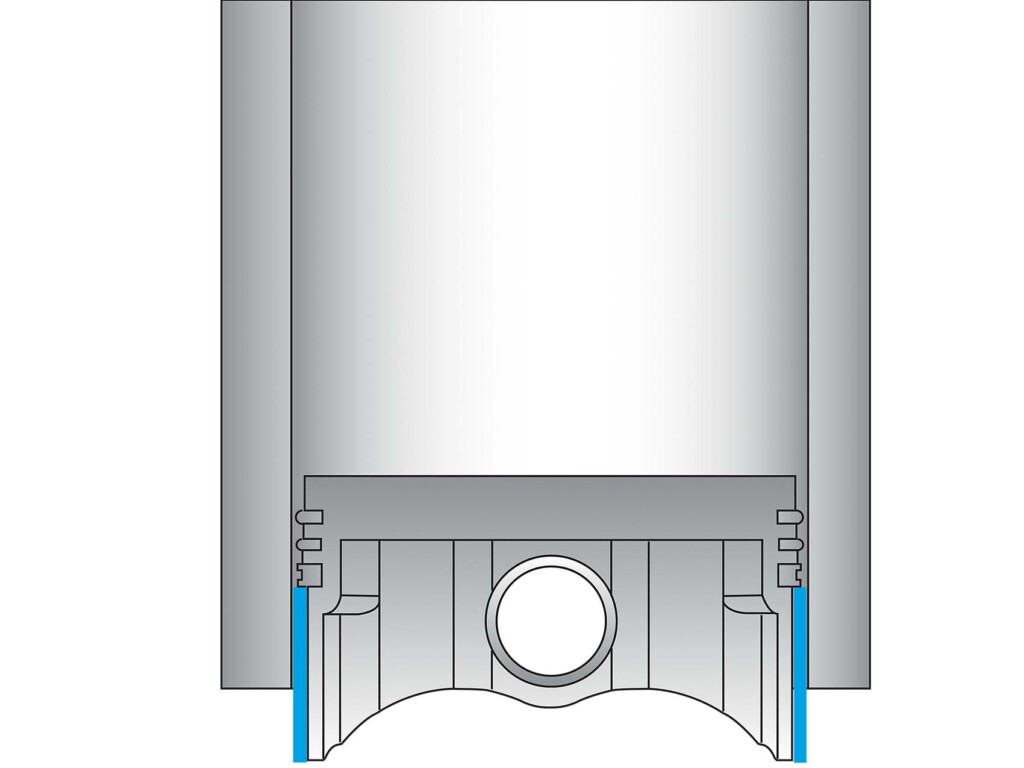

The abradable powder coating is applied thick on the piston skirts. When the engine is broken-in, the coating wears-in perfectly to the shape of the cylinder. This allows the piston to remain perfectly stable at BDC and provide more lubrication the entire time.

Piston Rock

Perhaps one of the biggest concerns of excessive clearance, piston rock occurs when there’s too much piston-to-wall clearance. As the piston goes up and down the cylinder, it can move side-to-side when it has too much room. “Piston rings don’t like rockover,” said Keith Jones, Director of Technical Sales at Total Seal. Although your OEM vehicle may experience some piston rock, it’s even more amplified in stroker engines as the piston drops below the cylinder bore when in BDC. This causes extreme piston rock which results in uncontrollable oil problems.”

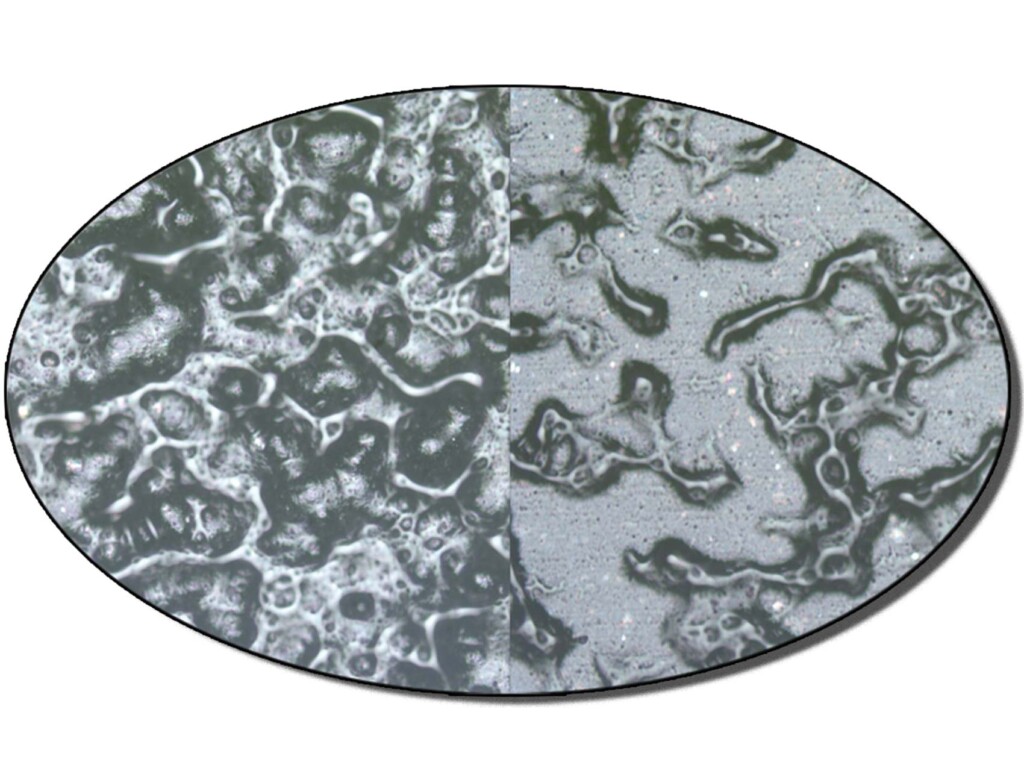

When the abradable powder coating is first applied, it is rough and fuzzy. Once you break-in the engine, it wears-in to the mating surface leaving behind a polished surface with micro pores that hold the oil in for more lubrication.

The Solution

Not too long ago, we received an engine at Club DSPORT that had some machine work done in Japan. The block machining was done so poorly that we had to re-hone the cylinders. This left us with perfectly good pistons that were too small for the cylinders. That’s when we explored abradable powder coating in an attempt to make the pistons work with the refreshed block. The coating eliminated our excessive clearance issues. The powder coating works by applying a thick coat that is almost too big for the cylinder. Once broken-in, the coating takes the shape of the cylinder and creates zero piston-to-wall clearance. The break-in will leave tiny abraded material in the oil and the larger particles will get trapped in the oil filter. When using an abradable powder coating on piston skirts, it creates the ideal fit to keep the piston stable. This reduces ring flutter, improves sealing, and extends the life of the piston and the rings. The tight fit also reduces piston rock noise, which is usually heard upon starting the engine for a few seconds. Although there is barely any tolerance, the oil in the coating’s pores along with the soft characteristics of the material ensures no damage to the cylinder.

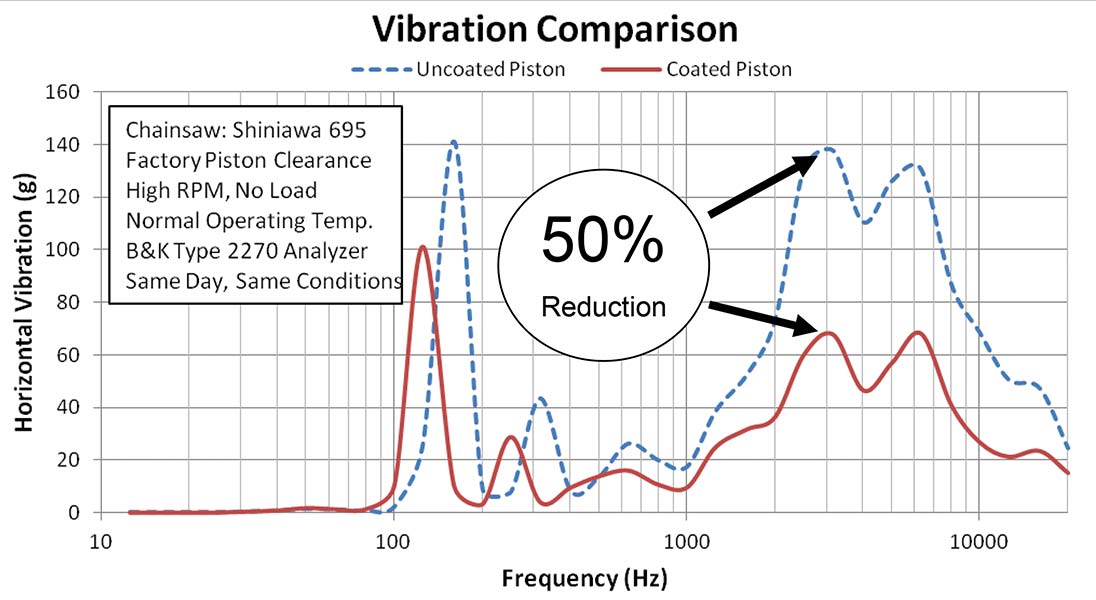

What better way to test for vibration other than a chain saw! Line-2-Line Coatings tested the abradable powder coating on a chain saw’s piston. The result was 50-percent reduction in vibration. The test was conducted on the same day with the same condition. The same test also resulted in reduced noise between the uncoated piston and the coated one.

Abradable Powder Coating

The abradable coating is a combination of material that is designed to wear off in order to take the shape of the mating surface and create a zero tolerance fit. The coating is made up of soft material that starts off thick and fuzzy when applied, then wears-in to the shape of the mating surface upon proper break-in. After the heat cycles from the break-in, the coating becomes polished with micro pores that hold the oil in to ensure constant lubrication for the part at all times. The result is a zero tolerance fitment that is established after the part is installed.

The abradable coating is a combination of material that is designed to wear off in order to take the shape of the mating surface and create a zero tolerance fit. The coating is made up of soft material that starts off thick and fuzzy when applied, then wears-in to the shape of the mating surface upon proper break-in. After the heat cycles from the break-in, the coating becomes polished with micro pores that hold the oil in to ensure constant lubrication for the part at all times. The result is a zero tolerance fitment that is established after the part is installed.

Jason Farrell, a top-running AMA Superbike racer, coated his pistons with an APC. On the fresh engine, the power was slightly lower given the tight build. After 700 race miles, the engine made more power and the dyno showed improved acceleration. The red dashed line is the APC coated engine when new, and the solid red line is the coated engine after the 700 miles of racing. The coating improved efficiency as it went through heat cycles.

Ideal Cases

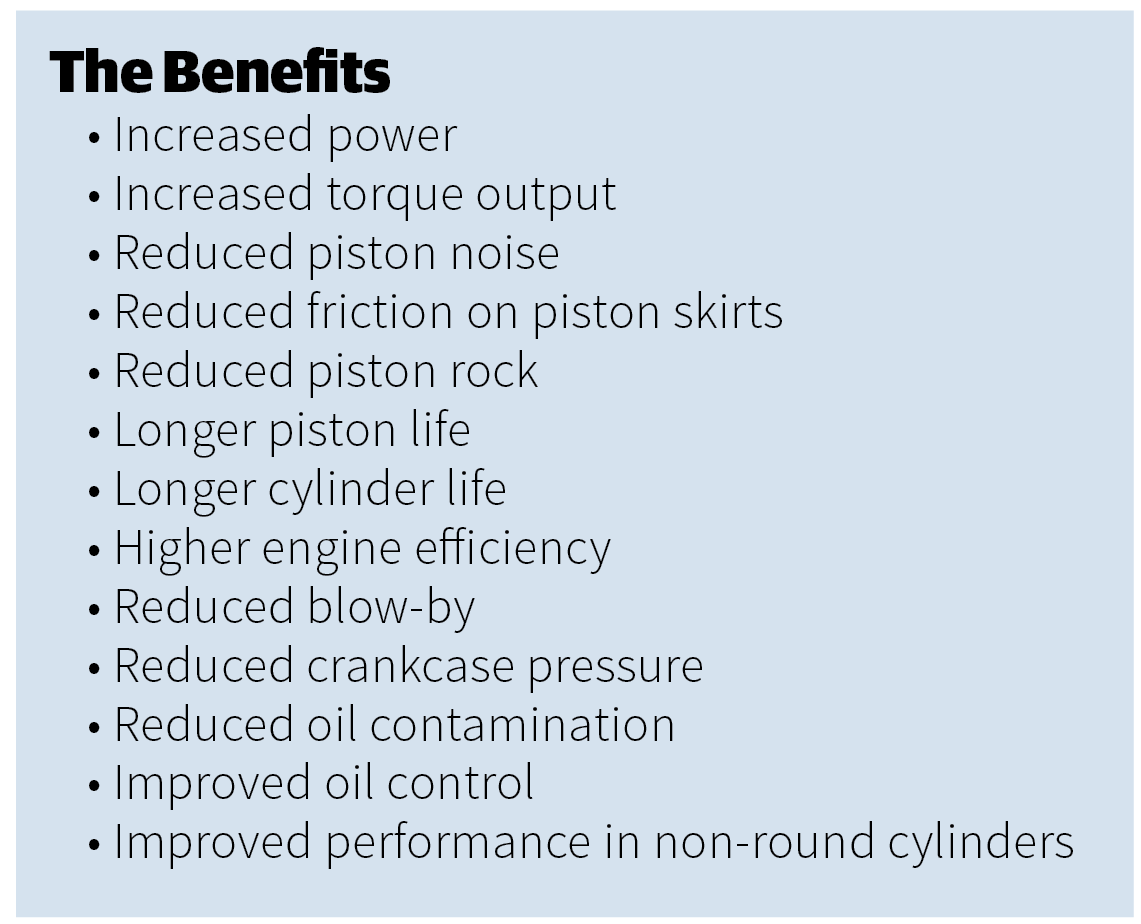

There are four situations where abradable powder coating could be of service in a piston situation: the design of the engine when the piston leaves the bore, excessive piston-to-wall clearance, refreshing the pistons, and performance increase. The design of the engine, like the Subaru EJ and FA series, forces the piston to leave the bore at BDC. Once the piston reaches BDC, extreme piston rock occurs which can cause oil control problems. The same goes for stroker engines. The pistons on the LS with the 4.0-inch stroker almost completely leaves the bore at BDC which causes extreme rock. Excessive piston-to-wall clearance problems happen when some material is taken out of the cylinders during honing while using the same pistons from before. Abradable powder coating creates that zero tolerance and eliminates the piston rock problems. The coating could also be used to refresh pistons, like the L2618 alloy pistons since they get softer over time. The coating can add some durability to it. Finally, having this additional seal in the cylinder increases engine efficiency, as it eliminates oil blow-by which decreases crankcase pressure.

The Bottom Line

When we coated the RB26 piston skirts from the engine coming from Japan, it costed us $36 per piston. In addition to that, a slight amount of assembly time to scotch-brite the piston to fit is consumed, and the additional time/cost spent to break-in the engine can also be added to the equation. Altogether, the process saved us hundreds of dollars by re-using the pistons rather than opting for an all-new, completely custom set. If you have good quality pistons but they don’t fit anymore after your block machining, this coating is a no-brainer. It adds some protection with better lubrication, zero clearance fitment, and increases the efficiency of the engine – what’s not to like?