The Right Clearance

Back in the early days of import performance, there was one very popular engine builder that used “pink” bearings on every Honda engine built. These pink bearings delivered the maximum amount of clearance. It was this engine builder’s belief that loose clearances were best. In actuality, just the opposite is true. Tighter clearances create higher oil film pressures which can support greater loads. Tighter clearances also reduce the possibility of cavitation erosion. Cavitation erosion occurs when vapor bubbles in the oil break. The resulting force can erode the soft surface of the bearing. Finally, tighter clearances in the rod and main bearings ensure that adequate oil is supplied to the top end of the engine, extending the life of the valvetrain. Ultimately, the ideal bearing clearance depends on a number of factors including oil viscosity, oil temperature range and journal diameters. So where do you start with clearances?

If you are running OEM recommended oil viscosities, a good starting point is on the “tight” end of the recommended clearances for the rod and main bearings. Some builders also use the 0.0010-inch rule that says to allow 0.0010-inch of clearance per inch of journal diameter. If a journal is 2.20-inches in diameter, the clearance by this rule would be 0.0022-inch. To ensure that this clearance is enough, engine developers might add up to 0.0005-inch at the start (a starting point as big as 0.0027-inch in this example). Along the way, the developers would continue to tighten up this clearance until evidence of too little clearance appeared. The spec just outside this too-little clearance would be just right.

If you are running OEM recommended oil viscosities, a good starting point is on the “tight” end of the recommended clearances for the rod and main bearings. Some builders also use the 0.0010-inch rule that says to allow 0.0010-inch of clearance per inch of journal diameter. If a journal is 2.20-inches in diameter, the clearance by this rule would be 0.0022-inch. To ensure that this clearance is enough, engine developers might add up to 0.0005-inch at the start (a starting point as big as 0.0027-inch in this example). Along the way, the developers would continue to tighten up this clearance until evidence of too little clearance appeared. The spec just outside this too-little clearance would be just right.

When racing engines have the coolant and oil pre-heated and circulated before startup, tighter clearances can be used. When thinner-weight oils are used, clearances can also be reduced. Currently, the majority of Winston Cup teams claim to be using a 10W-30 or 10W-40 synthetic racing oil. These engines feature a 1.850-inch rod journal diameter and a 2.000-main main journal. Some teams will run clearances of 0.0015-inch or less on the rods and under 0.0020-inch on the mains.

When measuring the rod and main bores with the bearings installed, remember to measure at the 12- and 6-o’clock positions as these will represent the areas of minimum clearance between the bearing and the rod or crank pin.

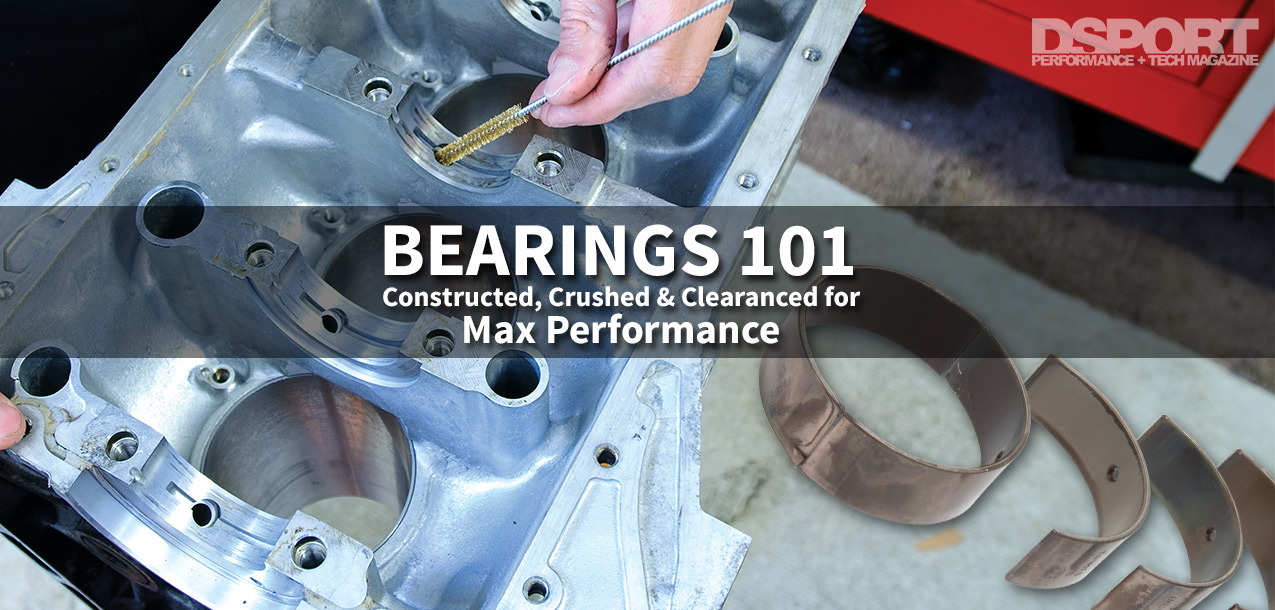

Always test fit prior to assembly. These aftermarket rod bearings are for the same engine. However, the thinner bearing is required on the stoker crank and rod combo.

Always test fit prior to assembly. These aftermarket rod bearings are for the same engine. However, the thinner bearing is required on the stoker crank and rod combo.

Getting Your Bearings Straight

[pullquote]THE RIGHT SET OF AFTERMARKET ENGINE BEARINGS DOES HAVE ITS ADVANTAGES[/pullquote] Some engine builders swear by OEM bearings over aftermarket high- performance bearings. After all, at factory power levels, many of the better OEM bearings can live 200,000-plus miles without incident. However, the right set of aftermarket engine bearings does have its advantages. In general, these bearings will perform the primary and secondary functions of a bearing at higher levels. Of course, no amount of material or manufacturing technology will protect a bearing from poor machine work, incorrect clearances, excessively dirty engine assembly procedures or inadequate lubrication. Always inspect your engine when you tear it down to see the condition of the bearings. If you aren’t comfortable in spotting potential issues, keep everything in order (or label it) and take it to the machine shop for an expert opinion.