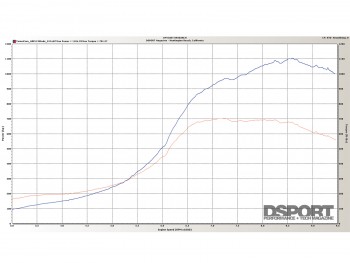

Falling Torque Curve, Rising Horsepower

Horsepower usually increases after peak torque RPM on most engines. This occurs because RPM increases faster than torque falls. In all cases, the fastest lap times result when you put the most horsepower (not torque) on the track. This is one reason friendly power and torque curves, when properly driven, give you faster, easier and more boring laps, as the car becomes easier to control.

Smooth Shift Recovery

A few years back, the Pro Modified drag racers pointed out that if you could hear, feel or see the shift from First to Second, it was going be a slow pass. Mike Hedgecock of Eagle Racing Engines builds 2,000-plus-horsepower engines for 2,400-pound RWD Pro-Mod door-slammers. These cars run the quarter mile in the low 6’s or high 5’s. These racers understand that tire grip must not be upset when a vehicle is already on the ragged edge of traction. To avoid an upset to grip, acceleration before and after the shift must be EXACTLY the same. This occurs when the horsepower at the shift RPM equals the horsepower at the engine RPM after the shift; the same horsepower to the tires before and after the shift. Optimizing the shape of the power curve, transmission gearing and shift points allows the vehicle to put down maximum power without upsetting traction.

The Drift Engine Exception

In setting up an engine for drift competition, the driver wants a power curve void of “automagic” traction control. Instead, a power curve that induces and carries wheelspin is desirable. One way to acomplish this is to race at engine speeds below peak torque. The swap to a larger-displacement, high-torque V8 engine can often provide enough torque at lower engine speeds below peak torque to get the tires spinning. As the engine speed is increased toward the peak torque RPM, the chances of recovering traction are eliminated. The addition of a centrifugal supercharger that adds boost as engine speed increases can also provide these drift-car optimized curves. Longer-duration camshafts can also be used to shift the peak torque RPM to a higher level. Of course, these setting are specialized only for dedicated drift vehicles and should not be used on competition or street-driven vehicles.

The Bottom Line

By understanding your engine’s power curve, you can make informed decisions about future upgrades while developing a friendly power curve to race smooth and fast. With increased control of the engine’s power, passes and laps may be a bit more boring, but you will be quicker.

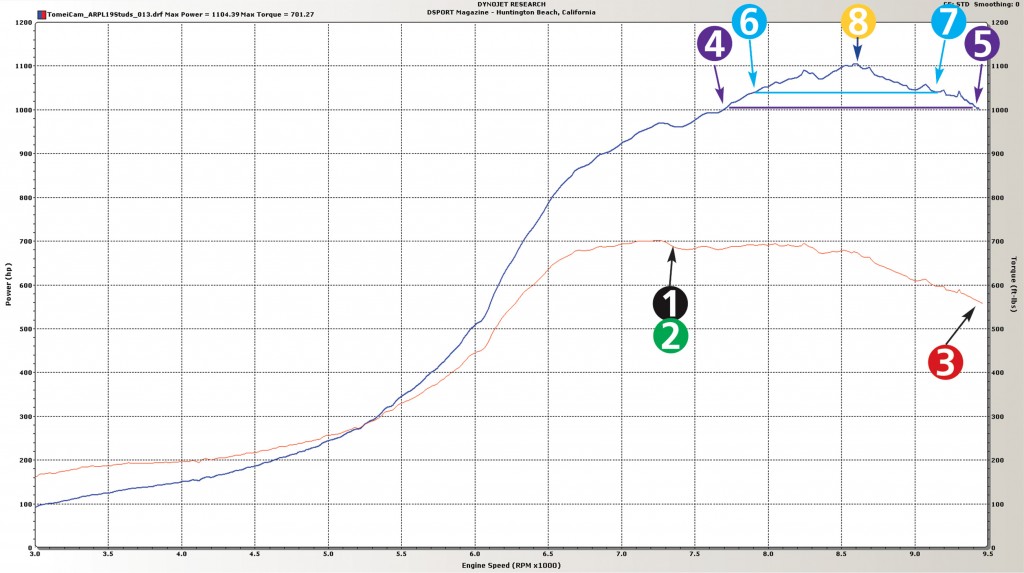

Dyno Curve Key Points

1) Lowest RPM that should be used on the track. Torque may remain constant along a shelf after this RPM.

2) Starting RPM for “automagic” traction control. Often below start point of quickest powerband. Ok to use to avoid downshift.

3) Maximum RPM/Redline. Sometimes, the engine redline won’t be high enough to see the full shape of the curve.

4) Ideal upshift-recovery RPM in the next taller gear, where horsepower after shift equals horsepower before the shift.

5) Shift at this engine speed on upshifts. Ideal upshift RPM to the next taller gear. Transmission gear ratios will affect point 4 & 5.

6) Alternative upshift-recovery RPM. When ratios between transmission gears are closer, points 4 & 5 move closer to each other.

7) Alternative upshift RPM point usable with a close-ratio gearbox. Notice that average horsepower between these points is higher.

8) Peak horsepower RPM. The closer race RPM to this point while accelerating, the quicker the lap times.

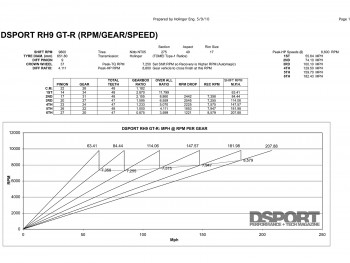

Gearing To The Curve

A vehicle’s transmission gearing will determine the drop in RPM upon upshifts. We’ve called the point that the RPM drops to on upshift the “upshift-recovery RPM.”

Ideally, the upshift-recovery RPM should follow two rules:

1) The upshift-recovery RPM should by higher than the engine’s RPM at peak torque. This will provide “automagic” traction control as the engine will be producing less torque as RPM increases.

2) The horsepower at the upshift-recovery RPM should equal the horsepower at the shift RPM. By delivering equal power to the vehicle before and after the shift, the suspension isn’t upset and the vehicle accelerates smoother and with more control.

Following the above rules, our Project RH9 GT-R must be shifted at 9,800 RPM or higher to avoid a drop of engine RPM below the peak-torque RPM of 7,250 RPM. With the new engine, we’ll take engine RPM to 10,500 RPM on the dyno to get the shape of the enitre power curve. This will allow us to pick the exact shift RPMs in each gear to satisfy the second rule. Besides providing the best balance and control, these shift points will also deliver the quickest acceleration as they cover the powerband of the curve with the highest average horsepower too.