Like the elegantly simple yet intriguingly complex rubik’s cube, setting up automotive suspension is a bit of a mystery that’s difficult to decipher. When analyzing an original 3x3x3 Rubik’s cube, there are a daunting 43,252,003,274,489,856,000 combinations in which you can orient the little squares. Even with over 43 quintillion combinations, there are people who can solve a cube in just seconds.

Text and Photos by Sami Sharaf / Illustrations by Paul Laguette

DSPORT Issue #161

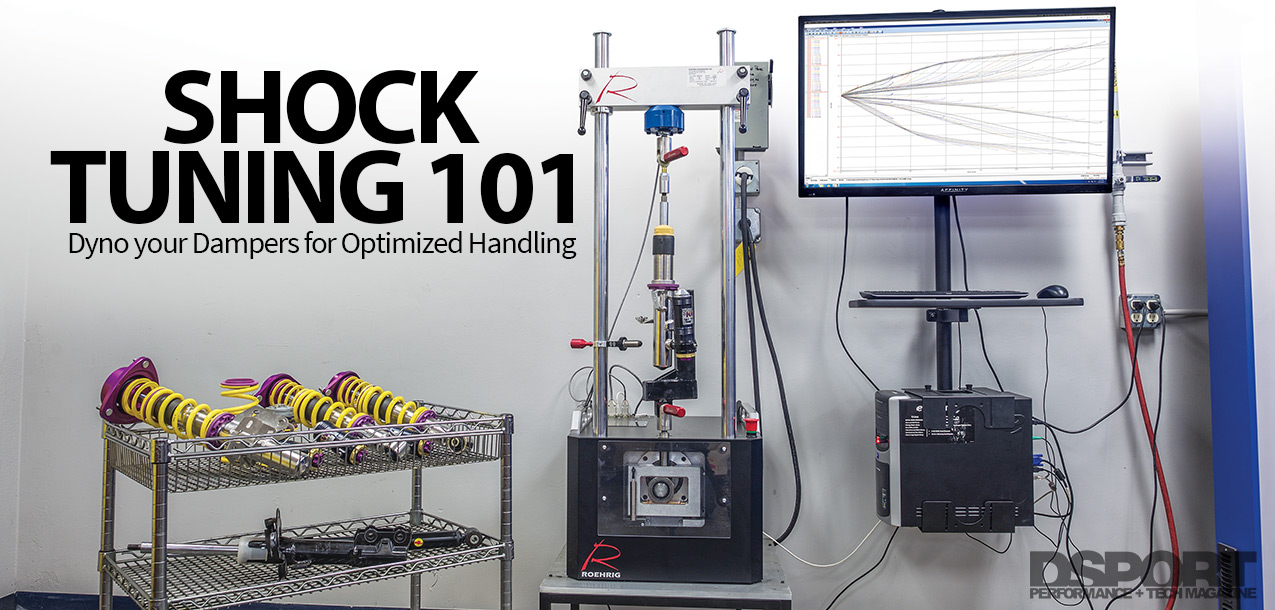

So what’s the key to solving intricate problems like Rubik’s cubes and the setup of automotive suspension? First and foremost, taking the time to analyze the system and how it operates is the most revealing step. Second, specialized computer software and the right tools can help tremendously in finding a systematic approach to the problem. When it comes to vehicle suspension, understanding how it works and combining that knowledge with the proper use of suspension tuning equipment, the various combinations can be easily selected and adjusted for optimal performance.

On many performance shocks, adjustments in compression and rebound force can be made with a simple turn of a dial.

On many performance shocks, adjustments in compression and rebound force can be made with a simple turn of a dial.

The Synergy

In general, the objective of the shock and spring combo is to stabilize the chassis and make handling predictable. This is manifested in various ways including the rigidity of the chassis, stiffness of the suspension, and the amount of travel available. In setting up these parameters, knowing the duties of the individual suspension components is imperative to understanding how the system works as a whole.  Likewise, it is important to note that the individual components that make up the system create an interaction that affects the overall performance.

Likewise, it is important to note that the individual components that make up the system create an interaction that affects the overall performance.

Springs

Springs suspend the vehicle at a set ride height, provide resistance to upward suspension travel and assistance to downward travel, and keep the tires planted to the ground. The method in which springs achieve these tasks is by resisting changes in tire position. For instance, when a vehicle moves down a road and encounters a bump, an upward force is applied to the wheel that travels across the bump. The upward force is then translated into the spring, which compresses. The compression in the spring effectively transforms kinetic energy into potential energy. When the spring expands, the stored potential energy is released and a cycle of oscillation is initiated.

Shocks

The oscillation encountered after experiencing a change in road surface could continue for a prolonged period of time and would render the vehicle unsafe and unpredictable. For this reason, it is necessary for the suspension to have a method of reducing the oscillation of the spring by converting the cyclical transformation of kinetic energy and potential energy into another form. This is where the shock absorber comes into play. Shocks act to dampen the oscillation of the spring by offering a resistive force and by converting the absorbed energy into heat.  The heat generated by the shock is then transferred to either gasses or oil contained within the body of the shock.

The heat generated by the shock is then transferred to either gasses or oil contained within the body of the shock.

Shock absorbers function in two directions, compression and rebound. Compression relates to the upward motion of the wheel and subsequent shortening of the shock. The downward motion of the wheel and corresponding elongation of the shock create rebound.

When operating in ideal conditions, the vehicle suspension keeps the tires in firm contact with the road surface. This allows the vehicle to respond to steering and braking inputs in a predictable manner. If the tire’s connection to the road surface were to become interrupted, the tire’s ability to perform its role in providing traction during acceleration or braking friction during deceleration would be compromised.

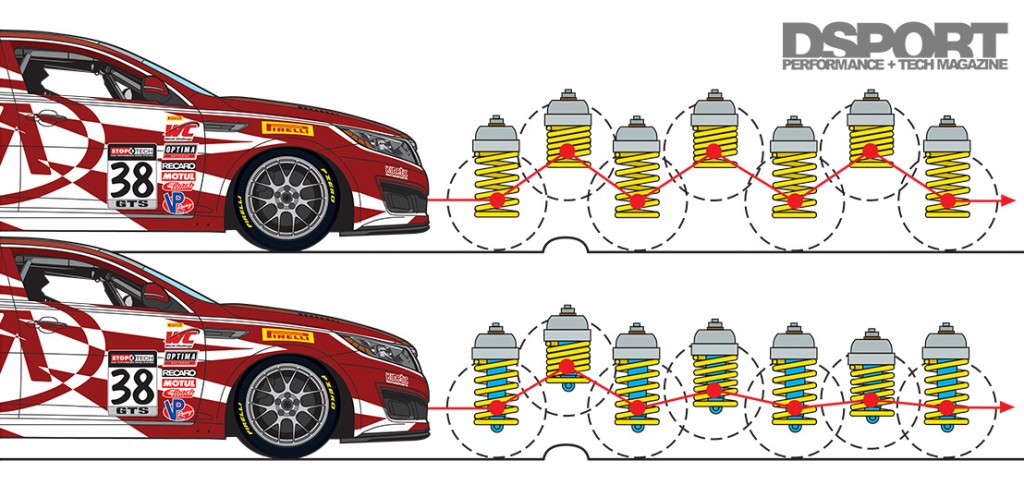

(Top) In a static state, the shocks are considered to be in neither rebound nor compression. (Middle) Under heavy braking, the front shocks are likely to experience compression whereas the rear shocks will rebound. (Bottom) During hard acceleration, the rear shocks compress, while the fronts rebound.

(Top) In a static state, the shocks are considered to be in neither rebound nor compression. (Middle) Under heavy braking, the front shocks are likely to experience compression whereas the rear shocks will rebound. (Bottom) During hard acceleration, the rear shocks compress, while the fronts rebound.