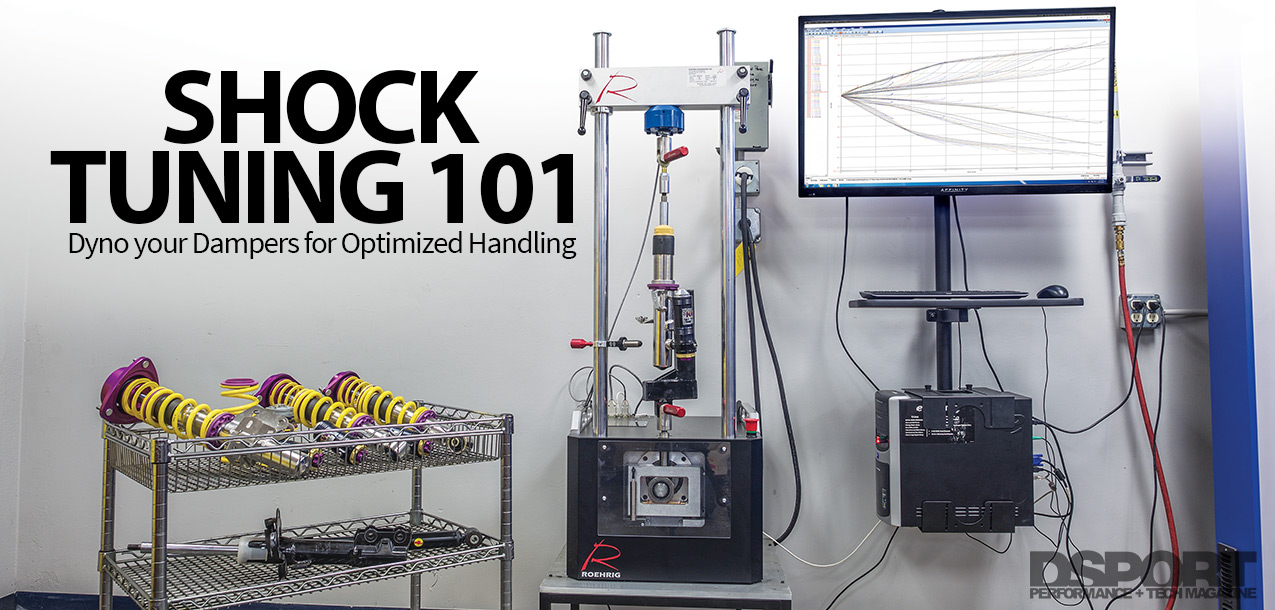

The Equipment

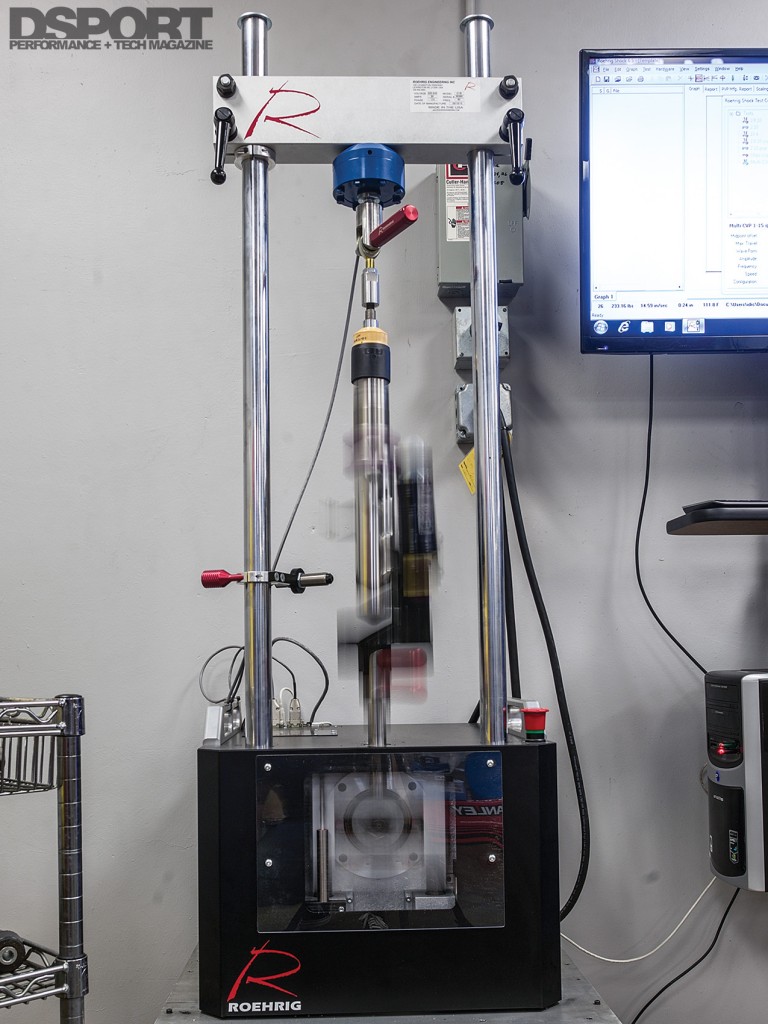

In an effort to build the best performing vehicles, we’ve focused on enhancing suspension performance by turning our attention to the aforementioned components. This quest has allowed us to broaden our knowledge of suspension and the equipment used to test it. In this case, the testing equipment is a shock dynamometer. Put simply, a shock dyno is a machine that measures the force created by the shock as it is compressed and extended at predetermined speeds.

In an effort to build the best performing vehicles, we’ve focused on enhancing suspension performance by turning our attention to the aforementioned components. This quest has allowed us to broaden our knowledge of suspension and the equipment used to test it. In this case, the testing equipment is a shock dynamometer. Put simply, a shock dyno is a machine that measures the force created by the shock as it is compressed and extended at predetermined speeds.

What does testing shock absorbers do for us? At the very least, it means knowing exactly how shocks perform. Many coilovers and adjustable shocks have tolerances in production, which may translate into substantial variances in operation. This means that the shocks on the right and left side of a car, even if set to the same adjustment, may not be performing equally.

Another useful parameter to understand is the confounding interaction between various shock settings. Many shocks on the consumer level offer adjustment ranges in compression and rebound but most manufacturers don’t disclose how setting one adjustment affects the other. Meaning, turning the adjustment knob on your damper not only changes the rebound, but may also affect the compression output. In this sense, the actual performance of the shock may become somewhat of an enigma once settings are changed.

A shock dyno is especially helpful in determining the condition of shocks. With time and use, many shocks will lose the ability to sufficiently dampen. This could be a result of damage, wear or improper use. Whatever the case may be, it is important to have a quantifiable means to determine the condition of shocks before moving forward with costly repairs or replacements.

Optimal Clicks

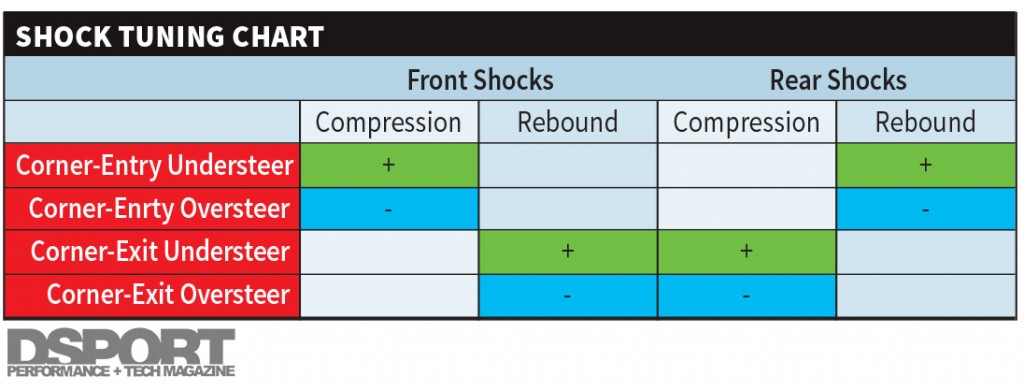

In adjusting suspension it is important to realize that there is no perfect setting. But it is possible to dial in suspension based on how the car is expected to perform. To find the optimal downward and upward force of the shock, a shock dyno can offer exact measurement of force in the shock’s compression and rebound phases. Armed with this data, changes can be made to the shock settings in compression and rebound to influence the vehicle weight transfer. As such, creating more rebound force on a corner of a vehicle will result in less weight on that corner when the shock is in the rebound phase. On the other hand, a reduction in rebound force on a specific corner will result in more weight on that corner during the rebound phase. The compression settings have the opposite effect. When more compression dampening force is set on a corner, the vehicle will exhibit more weight on that corner when the shock is in the compression phase.

The KW Suspension Variant 3 coilovers we tested feature separate dampening adjustments in both compression and rebound. The rebound adjustments had a total of 16 settings while the rebound adjustments could be set to 12 distinct force outputs.

The KW Suspension Variant 3 coilovers we tested feature separate dampening adjustments in both compression and rebound. The rebound adjustments had a total of 16 settings while the rebound adjustments could be set to 12 distinct force outputs.

Roehrig Engineering, Inc.

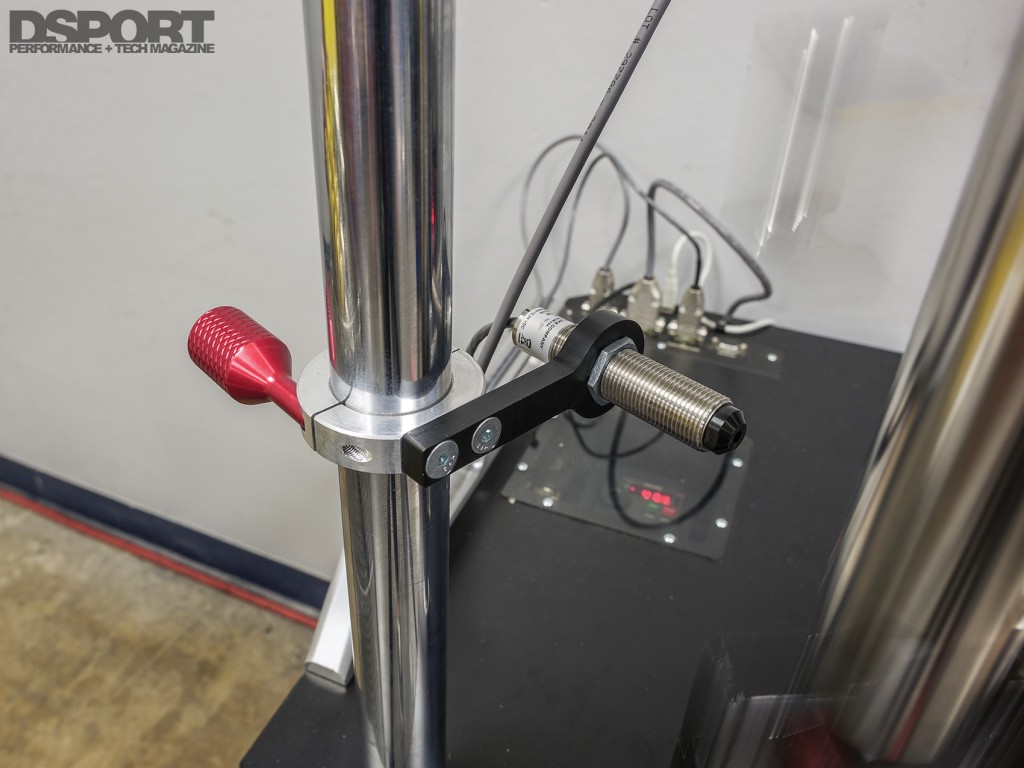

In the late 80s, Kurt Roehrig helped pioneer shock-testing equipment. Through years of experience, he engineered and produced a line of industry leading shock dynamometers that rely on electromagnetic linear motors. The use of electromagnetic actuators allow shock dynos to operate with extreme precision and efficiency. While most racers won’t be clearing out a spot in their garage for their very own shock dyno, knowing the capabilities of this powerful piece of testing equipment can be an important asset in determining the proper setup of your vehicle’s suspension.