Finding Exhaust Centerline

Degreeing the Exhaust camshaft

1. Find the camshaft manufacturer’s exhaust centerline specifications on the camshaft card or in the catalog. This number represents the point in crankshaft degrees where the exhaust valve is lifted to its highest point.

2. Rotate the crankshaft until the exhaust lobe begins to open the exhaust valve. Remember that you must always rotate the engine in its standard direction of rotation. Never go the opposite way as it may create slack in the timing belt or chain that will produce incorrect readings.

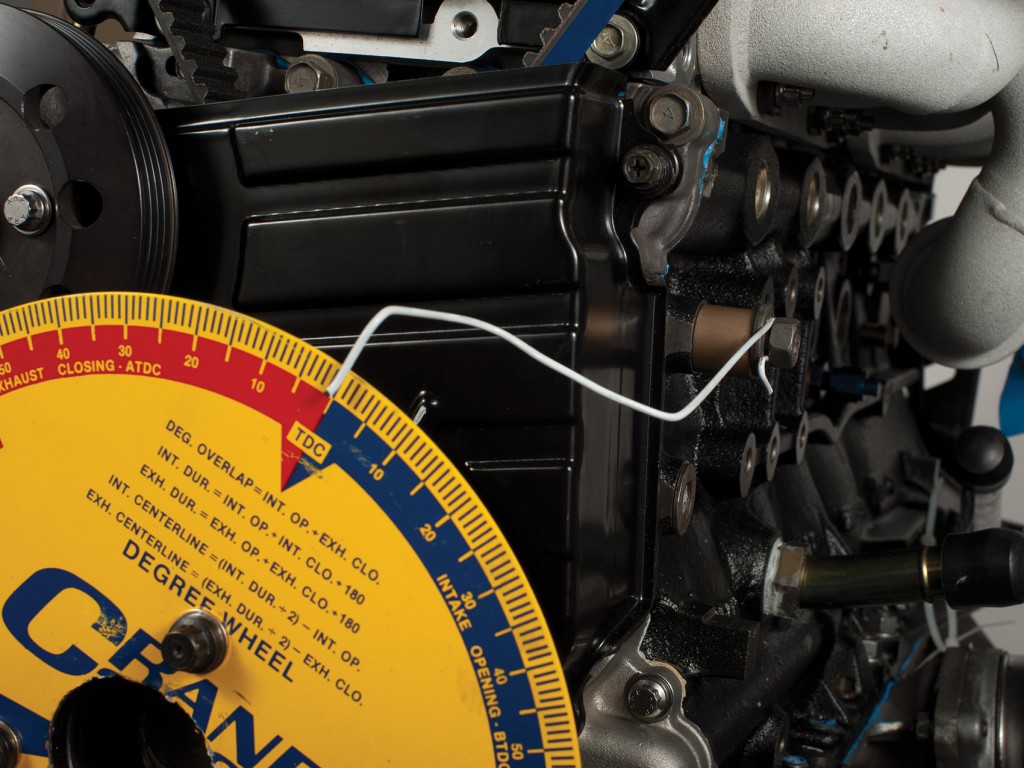

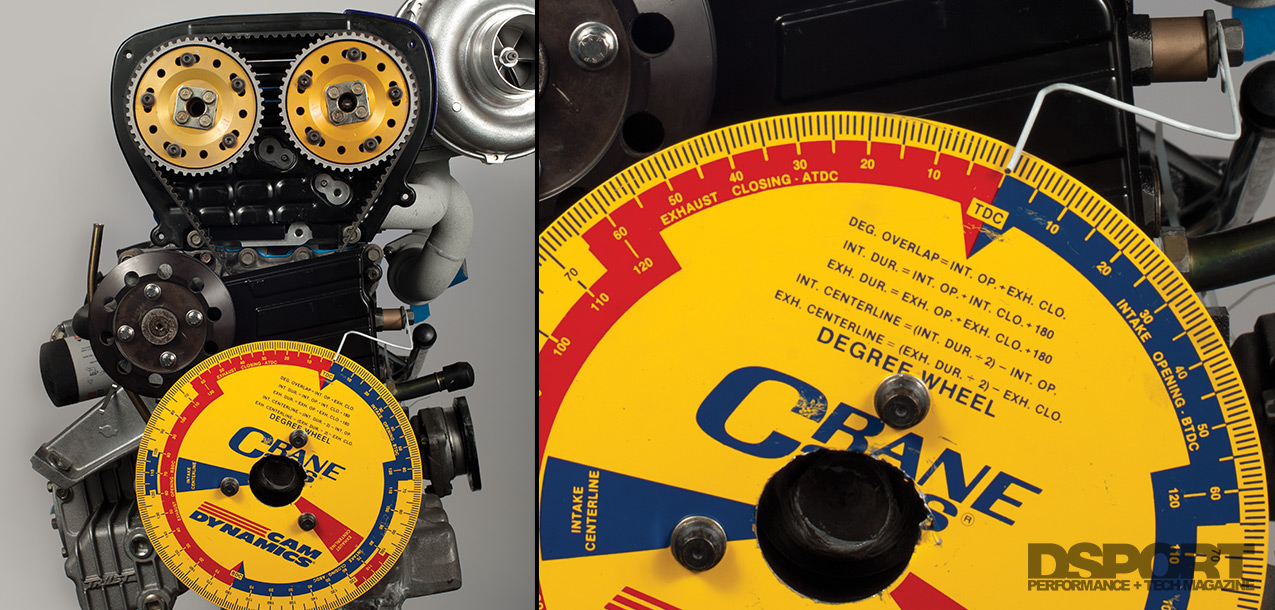

3. Once the exhaust valve begins to open, look at the degree wheel and see where the “exhaust centerline” region is located. Rotate the crankshaft until the 120~130 degree range before the exhaust centerline band.

4. At this point, a dial indicator must be mounted and set up to measure the valve movement at the exhaust valve. The gauge is not going to be used for an actual measurement, only to locate the point at which the maximum lift on the valve occurs.

5. Set up the dial indicator so that it shows at least .100” in measurement.

6. Now here is the part that requires finesse. Slowly rotate the crankshaft while watching the dial indicator. Once you get to 5 degrees before the manufacturer’s specified exhaust centerline, record the values indicated on the dial indicator.

7. Rotate the crankshaft a single degree and record the dial indicator numbers. Repeat until you are five degrees past the manufacturer’s exhaust centerline specification.

8. During this 10-degree rotation, the needle of the dial indicator will move in one direction (while the valve was still being lifted), then it will stop (when the valve reaches peak lift) and finally it will change direction (as the valve started to close). This should all occur as you rotate the crankshaft from 5.0 degrees before to 5.0 degrees after the manufacturer’s specified exhaust centerline.

9. The point when the needle stops (or the value is the smallest recorded) is the actual exhaust centerline of the exhaust camshaft in the engine.

10. Note if the measured value is different than the manufacturer’s specified value.

11. If you wish to set the exhaust cam timing to the cam manufacturer’s specified value, an adjustable cam sprocket will allow you to dial in the camshaft timing to the manufacturer’s specification.

12. After adjustments are made to cam timing via cam sprockets, repeat steps 2 through 10 until the cam is “Zeroed” properly.

Any Questions?

Q: My Honda B-series spins counter- clockwise so a standard degree wheel won’t have the correct numbering. Is there a special degree wheel for engines that spin counter-clockwise?

A: Yes. There are a few manufacturers that produce degree wheels that have the degree marks and numbering in place for both clockwise and counter-clockwise spinning engines.

Q: My actual TDC mark found with the piston-stop method is off about two degrees from the factory mark on the balancer. Why is it different and what should I do?

A: If you have an aftermarket crankshaft or an aftermarket harmonic balancer, it’s possible that the keyway or mark on the crankshaft or balancer may be off a bit. This is a pretty rare occurrence. However, having cam sprockets that don’t exactly match up when cylinder one is at TDC of the compression stroke is more common. This is often the result of a milled cylinder head or milled block that can induce slack in the timing belt on the idler side.