Choking Performance

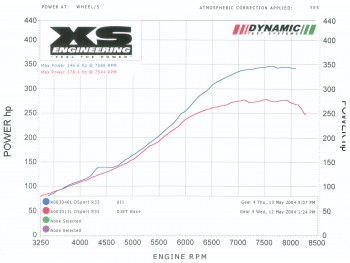

Before starting the dyno tune, we decided to swap our A’PEX Integration power filters for a set of the company’s Power Funnels. The Power Funnels feature a cast radius inlet that blots directly to the airflow meter. For filtration, A’PEX includes a red felt like material that is supposed to be sandwiched between the Power Funnel and the air flow meter. We followed the directions and proceeded to dyno tune the vehicle. The base program supplied with the Power FC D-jetro was definitely not setup for our giant injector and big twin turbo combination. As we tuned, we brought the horsepower up from 260 to nearly 400 horsepower at the wheels. However, something didn’t seem right. The engine seemed to struggle to make the desired boost level and power seemed off for the boost pressure we had dialed up to (1.50 bar).

Since we had never dyno tested on pump gas before with the 4wd dynamometer, we weren’t that sure if 400 wheel horsepower was a good or bad number for our car. In any case, the plan was to put the GT-R in 2WD configuration and try some passes on the XS Engineering DynoJet the following day.

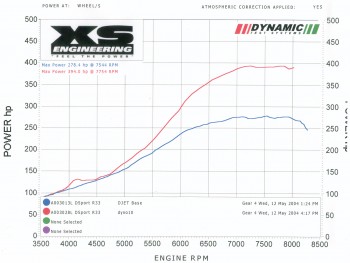

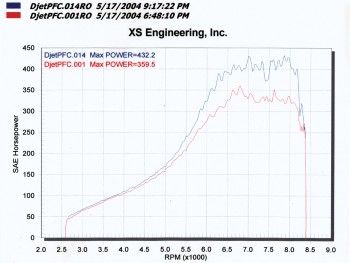

On the 2WD dyno, we expected that we might see some higher horsepower figures. What we found is that it was even harder for our GT-R to reach the desired boost level. It just couldn’t seem to make over 1.0 bar when subjected to the load of the DynoJet. We looked and looked again at every possible connection from the turbo outlet to the intake manifold inlet and found that everything was in order. Still, the best we could do on the DynoJet was just 360 horsepower. Running out of ideas, we decided to remove the Power Funnels with its felt filters and try another pull. The result was extraordinary. The engine rocketed to 1.30 Bar and power hit the 430 mark at the wheels. While this number was still 50 to 100 horsepower shy of where we believe the ultimate numbers will fall, the progress made was considerable. We followed this dyno test with the test of the carbon-fiber driveshaft. The carbon fiber driveshaft was 16 pounds lighter and just half the weight of the factory piece. On the dyno, the carbon fiber shaft showed a horsepower advantage through most of the rpm range. However, the excessive rich air-fuel mixtures on the top end on the powerband didn’t allow the driveshaft to truly showcase its value.

BASELINE

|

PEAK 278.4 WHP

|

Boost: 16.2psi

|

TEST 1 A’PEX Integration POWER FC D-Jetro

|

PEAK 346.6 WHP

|

Boost: 16.2psi

|

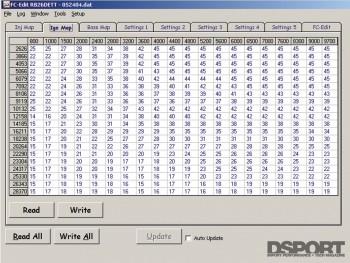

| Swapping over from the L-Jetro (Mass Air Sensor) POWER FC to the D-Jetro (Speed Density) version requirred a complete retuning of all fuel and igntion maps. We started on the 4wd dyno at low boost levels to begin the process. Without increasing boost levels, we were able to find some major power gains over the base program. |

TEST 2 RAISE BOOST LEVEL W/ POWER FC

|

PEAK 394.0 WHP

|

Boost: 21.7psi

|

| Raising the boost level found some significant power gains even with rough tuning. |

TEST 3 REINSTALL SUPER INTAKE FILTERS

|

PEAK 432.2 WHP

|

Boost: 17.4psi

|

| All of the previous dyno runs in the session were made with the Super Funnel air horns with filters in place. These used a “felt” element that turned out to be very restrictive. Once we put our original Super Intake filters in place, boost response and power soared. Now on low boost we made more power than high boost. Time ran out to retune at the high boost level. Our target will be 500-plus horsepower on pump gas. |