Air-Fuel Ratios

In using the FC Datalogit with the AEM UEGO system, we noticed some problems with the air-fuel ratio being displayed in the datalogs. Both 0-5volt output channels from the AEM UEGO were fed into two separate input channels of the FC Datalogit. However, it appeared that the signal was corrupt and experiencing a dropout. The reading would look like 3v- 3v-0v-3v-0v-3v, instead of being a consistent 3v-3v-3v signal. In most cases, a problem like this is traced to a garbage-in-garbage-out type error; this error results when a bad input is put into a converter and the result is a bad output. Believing that the input had to be bad, we first tried swapping each of the components in the AEM dual-band UEGO system. First we swapped the O2-sensors, then the amplifier box and finally the main harness. None of this had an effect on the A/F ratios being datalogged. Attention was next turned to eliminating the potential for a dirty power supply of a bad ground. The AEM UEGO was grounded at the cylinder head, at the battery at the chassis and, still, the problem still existed. The power supply was then attached directly to the battery and still no progress was being made. It got so bad, that we resorted to wrapping aluminum foil around the amplifier box and even the Power FC ECU and still no change. The bottom line was that the AEM UEGO system was functioning flawlessly and that its power and ground were also stable. The only part left to test was the FC Datalogit itself. The FC Datalogit had performed flawlessly in logging all of the sensors tied into the Power FC. However, we needed to see if the signals hooked directly into four auxiliary 0-5-volt input on the FC Datalogit were being processed correctly. To test, we hooked up a AA battery to the channel 1, 2, 3 and 4 inputs and took a look at the datalogs. Even with a steady battery input of 1.55volts from the AA, the datalog was still showing the signal dropout. We had isolated our problem. While all other aspects of the FC Datalogit were functioning correctly, the analog-to-digital signal converter in the FC Datalogit was not functioning properly. The A/D converter is supposed to read an analog voltage of zero to five volts and convert this into a digital signal for the laptop to understand. It wasn’t doing its job.

Once again we experienced a setback. With no other FC Datalogit units in the States, we wouldn’t be able to datalog the air-fuel ratios from the AEM UEGOs. We weren’t even sure if the numbers that we had extracted up to this point were valid. Not only were we set back to square one again, but we also had lost our shoes and someone sprinkled tacks on squares two, three and four.

From a combination of frustration and desperation grew a pretty good idea. Why couldn’t we run the 0-to-5 volt signals from the AEM dual-channel UEGO directly into the O2-sensor inputs on the Power FC? If this would work, we could at least datalog the voltages from the AEM UEGO. By knowing these voltages, we could look up the corresponding voltages in the supplied chart from AEM.

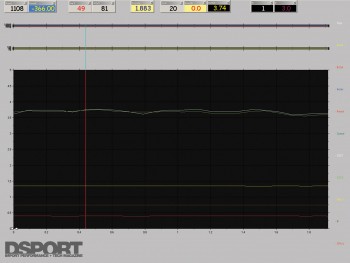

We decided to give our plan a try as we hooked up the AEM UEGO outputs directly into the Power FCs front and rear O2-sensor inputs. We then hooked up the FC Datalogit to see the results. By disconnecting the O2 sensors from the harness, the output of the AEM UEGO should read a steady 4.0 volts. That’s exactly what the Power FC’s front and rear O2 sensor input was reading. Now, we had proven that the AEM UEGO system was functioning properly and we had a way to datalog clean signals from the AEM UEGOs.

Good News and Bad News

The bad news came on three fronts. First, with the deadline for this issue approaching and a seemingly never- ending line of cars scheduled for dyno time at XS Engineering, we were restricted to looking at the datalogs from street driving only. Second, the datalogs were showing air-fuel ratios much richer than we had thought we were experiencing during out dyno tuning. Third, our homemade exhaust crossover pipe gasket had failed leaving us with a considerable exhaust leak that was hurting performance.

The good news came on two fronts. First, the gaskets that we ordered from Japan arrived and allowed us to cure our exhaust leak (hopefully for good). Second, we now have an accurate measurement that will allow us to dial-in air-fuel ratios that maximize performance and reliability. The minor adjustments made from street tuning have already provided incredible gains in response, performance and fuel economy. When we get back on the dyno, we won’t be surprised to see 500-plus or horsepower on 91-octane with boost and response curves that we never believed possible with turbos so big.

With a set of drop-in A’PEX Integration cams and some adjustable sprockets, we should be able to hopefully see close to 550 horsepower on pump gas. As for the power output on race gas, we expect close to 800 very-usuable wheel horsepower. Maybe 9s can happen on the stock short block after all.