DELICIOUSLY QUICK

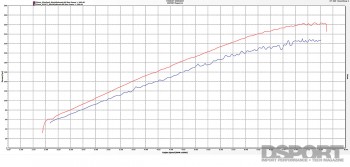

Equipped with the 75mm CARB-legal pulley and 91-octane in the tank, we established a baseline number of 230.44 wheel horsepower on our Dynojet 424XLC2 dynamometer. Without unstrapping the vehicle from the dyno, we popped the hood and installed the Delicious Tuning flex-fuel kit in just under an hour. This setup utilizes -AN fittings, E85-compatible braided hoses and a plug-and-play harness to connect the Delicious Tuning box to the ECU. After installing the flex-fuel kit, we added a full 10 gallons of E85 to the nearly empty tank and let Bill Knose fine tune the parameters. The blend of 91-octane and E85 in the tank that yielded an ethanol content of 67-percent. A quick ECU reflash and a few tuning adjustments later, our Project FR-S registered 263.44 peak wheel horsepower to the roller. By simply switching to the flex fuel (and making the proper adjustments), our FR-S gained a stout 33 peak horsepower and picked up power across the entire RPM range.

Equipped with the 75mm CARB-legal pulley and 91-octane in the tank, we established a baseline number of 230.44 wheel horsepower on our Dynojet 424XLC2 dynamometer. Without unstrapping the vehicle from the dyno, we popped the hood and installed the Delicious Tuning flex-fuel kit in just under an hour. This setup utilizes -AN fittings, E85-compatible braided hoses and a plug-and-play harness to connect the Delicious Tuning box to the ECU. After installing the flex-fuel kit, we added a full 10 gallons of E85 to the nearly empty tank and let Bill Knose fine tune the parameters. The blend of 91-octane and E85 in the tank that yielded an ethanol content of 67-percent. A quick ECU reflash and a few tuning adjustments later, our Project FR-S registered 263.44 peak wheel horsepower to the roller. By simply switching to the flex fuel (and making the proper adjustments), our FR-S gained a stout 33 peak horsepower and picked up power across the entire RPM range.

TO THE LIMIT

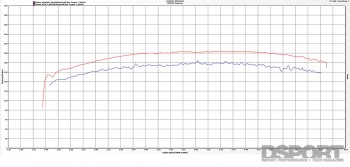

[pullquote]IT WAS TIME TO EXPLORE THE NON-CARB-LEGAL CAPABILITIES OF THE UPGRADES[/pullquote]While we were stoked to eclipse the 250 wheel horsepower mark, a stock block FA20 engine with a proper tune can support just over 300 wheel horsepower. It was time to explore the non-CARB-legal capabilities of the upgrades. Since we had already tested and installed a Perrin Performance exhaust, we estimated that any gains from another cat-back exhaust would be negligible as the catalytic converter and header would likely pose the greatest restriction of exhaust flow. Quite simply, we needed an “off-road” exhaust solution. On top of that, we turned to a smaller pulley to achieve more boost.

ALL ABOUT FLOW

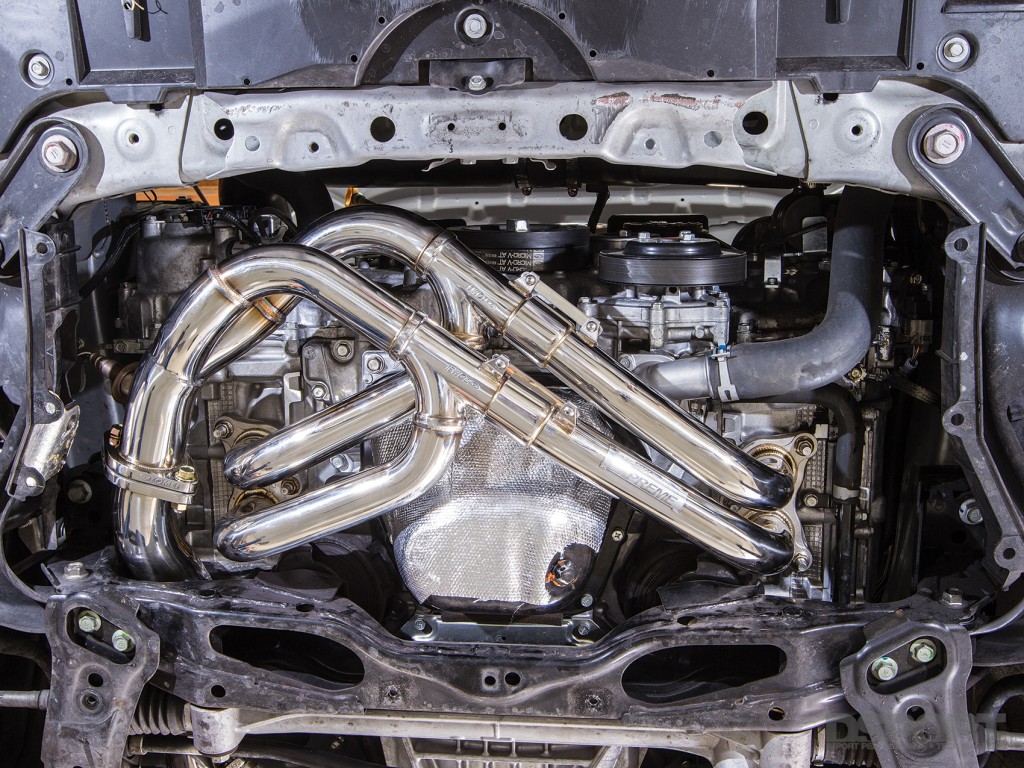

With a forced-induction setup, simply deleting the catalytic converters could greatly improve exhaust flow efficiency. Since the FR-S/BRZ utilizes both an upstream cat located on the header and a downstream unit on the downpipe, we needed to find a suitable replacement for at least those two pieces. Instead of piecing a bunch of different parts together, we opted for a complete header-back solution from TOMEI Powered.

With a forced-induction setup, simply deleting the catalytic converters could greatly improve exhaust flow efficiency. Since the FR-S/BRZ utilizes both an upstream cat located on the header and a downstream unit on the downpipe, we needed to find a suitable replacement for at least those two pieces. Instead of piecing a bunch of different parts together, we opted for a complete header-back solution from TOMEI Powered.

In place of the factory units and the Perrin exhaust, we chose a forced-induction friendly setup consisting of TOMEI Powered’s stainless-steel equal-length header, joint pipe, titanium straight pipe and titanium TYPE-80 exhaust system. While TOMEI Powered also offers an unequal-length header, we chose the equal length system for its top-end performance. Unlike some of the other offerings on the market, TOMEI Powered’s EXPREME exhaust offerings feature full TIG-welded construction, optimized pipe lengths and angles, thicker flanges, necessary gaskets and hardware. Compared to the factory system, the TOMEI Powered setup sheds nearly 40 pounds of weight. Removal of the factory system proved straightforward and installation of the exhaust went without hiccups as the system bolted directly to the factory locations. TOMEI Powered also includes a thermal insulation sheet to protect the oil pan from heat radiating from the header. With the new exhaust system bolted up, we shifted our focus back to the engine bay and swapped out the 74mm CARB-legal supercharger pulley for a smaller 69mm unit from Delicious Tuning. The 5mm decrease in pulley size translates to a blower that spins faster and delivers an approximate 2.0 psi increase in boost pressure.