PROJECT KA24 UPDATE

Knocking On Wood

While Project Silvia has made leaps and bounds forward, Project KA24 has taken a few steps back. After having installed the new wiring harness and all the ancillary engine parts required to get the car running, Project KA24 was back on the road for it’s engine break-in period. After a few hundred miles, however, Project KA developed a bit of rod knock. Determined to find the problem, we’ve removed the KA engine and are currently in the process of disassembling the block to determine how the failure occurred and to how to prevent it from happening in the future.

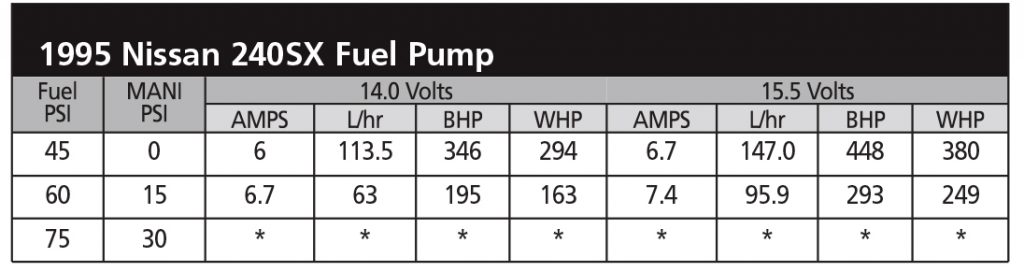

With the long block removed from the engine, we took this opportunity to further prep the engine for the turbocharger setup and this meant addressing the factory fuel system. For informational purposes, we removed the stock fuel pump and had it flow tested to see how it would perform under boosted conditions. We definitely don’t recommend the factory fuel pump for any turbocharged applications, and a quick glance at the flow chart will explain why.

Fuel Supply and Demand

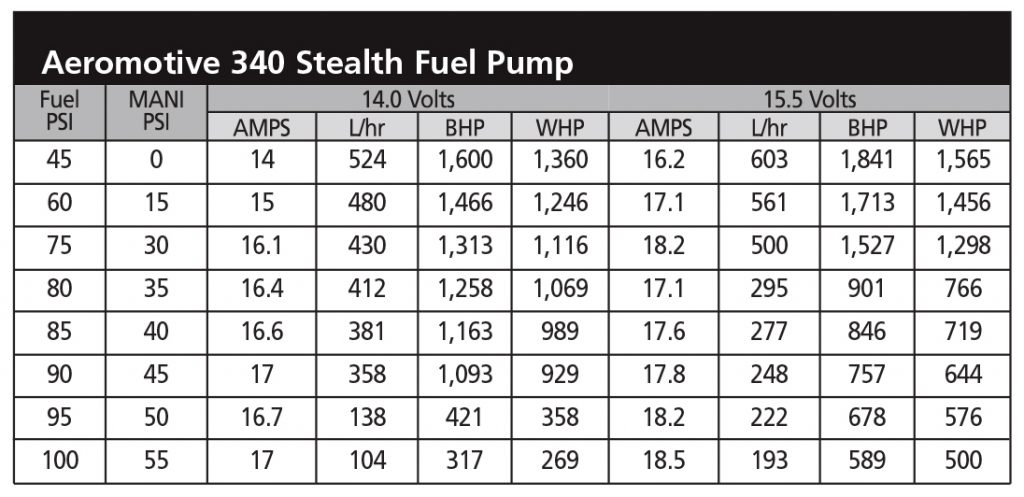

Since Project KA24 has considerably higher peak horsepower aspirations, we opted for a higher-flowing fuel pump and fuel injectors to match. To initiate fuel delivery, Project KA24 is now outfitted with Aeromotive’s 340 Stealth Fuel Pump. Aeromotive claims this pump fits in most common drop- in in-tank applications with minimal modification while providing consistent fuel output at higher fuel pressure levels. To test this claim, we sent the Aeromotive 340 Stealth to our test facility where it underwent the same testing as the factory KA pump.

Since Project KA24 has considerably higher peak horsepower aspirations, we opted for a higher-flowing fuel pump and fuel injectors to match. To initiate fuel delivery, Project KA24 is now outfitted with Aeromotive’s 340 Stealth Fuel Pump. Aeromotive claims this pump fits in most common drop- in in-tank applications with minimal modification while providing consistent fuel output at higher fuel pressure levels. To test this claim, we sent the Aeromotive 340 Stealth to our test facility where it underwent the same testing as the factory KA pump.

Flow Chart 1

NOTES: *Full bypass valve opening occurs at 62-63 psi @ 14V

With a little over 15-pounds of positive manifold pressure, the factory fuel pump’s bypass valve would inevitably open, causing an irregularity in fuel delivery. Additionally, at a 14.0 volt standard, the factory pump is only able to flow 63.0 liters-per-hour of fuel. This amount is enough to support only 163 whp, a peak number that should easily be surpassed by a properly-built turbocharger system pushing 15-pounds of boost. Therefore, unless the turbo system produces only minimal amounts of horsepower, a rising rate regulator coupled with the factory fuel pump is not the optimal combination for boosted KA fuel delivery.

Flow Chart 2

NOTES: Bypass opens 86-90 PSI @ 14V

(Chart 2) The 340 Stealth pump flowed numbers that were more than adequate for our needs, showing a 480 lph flow rate at the same 14.0 volt and 15 psi positive manifold pressure. Even with positive manifold pressure as high as 40 psi, the pump is still able to flow over 380 liters-per-hour at 14.0 volts and support applications making 989 whp. Beyond that, the 340 Stealth pump’s bypass valve begins to open, reducing the volume of fuel delivered consistently.

(Chart 2) The 340 Stealth pump flowed numbers that were more than adequate for our needs, showing a 480 lph flow rate at the same 14.0 volt and 15 psi positive manifold pressure. Even with positive manifold pressure as high as 40 psi, the pump is still able to flow over 380 liters-per-hour at 14.0 volts and support applications making 989 whp. Beyond that, the 340 Stealth pump’s bypass valve begins to open, reducing the volume of fuel delivered consistently.

With an adequate fuel pump in place, we chose a set of Fuel Injector Clinic 1,100 cc/min injectors to complete the fuel delivery at the intake manifold. This combination of pump and fuel injectors needs a proper pressure regulating solution to be used efficiently; we’ll explore that avenue in the next installment of the KA24 vs SR20 battle. Additionally, we should have the rod knock issue sorted out, after which we’ll report our complete findings here.

Next Round: KA24 vs. SR20

The next round of improvements for Project SR will include upgrading the fuel supply to remedy the fluctuating fuel pressures that were observed at the dyno. An S14 fuel tank upper plate with larger supply lines along with an independent relay should stabilize the fuel pressure at peak boost pressure. For Project KA, the block has been put under the microscope as we research the source of the bearing failure, remedy the problem and get the KA back into action. Fabrication of a new downpipe and intercooler plumbing will also be completed, along with forced induction tuning of the engine management. Stay tuned as we get closer to the final battle between the KA and the SR.

Follow the KA24 vs SR20 Battle

1) SR20DET vs KA24DE | Which is Nissan’s Best Four Cylinder?

2) D’Garage Silvia | Preparing For the KA vs SR Battle

3) KA24DE vs SR20DET Act II | Preparing the KA for Boost

4) KA24DE vs SR20DET Act III | SR20DET Heads Up

5) KA24DE vs SR20DET Act IV | Port Flow Design Readies our KA24DE Head

6) KA vs. SR Battle: Act V | International SR23 – Built Right And Ready To Fight

7) SR20 Steps Forward, KA24 Gets Knocked Back | KA vs SR Update