Making more horsepower and going fast is both fun and rewarding; however, there’s really no point to any of it if you cannot stop quickly and safely. While most factory braking systems prove adequate for the daily commute, going to the track or even spirited driving through the canyons could quickly expose the shortcomings of stock equipment. Fortunately, brake components can be upgraded to rein in the speed, helping you to slow down to go faster.

By Richard Fong

DSPORT Issue #171

Factory brake systems often feature a compromised blend of components optimized to provide adequate cold braking performance, longevity and reduced brake dust production. These are key criteria for a streetcar. On the other hand, a performance enthusiast is going to be more concerned about brake feel, brake fade and stopping in the shortest distance possible. Brake systems include seven key components, each of which can be improved to suit the purpose of your vehicle. Some brake components are wearable items that can be upgraded for a reasonable or even reduced cost compared to stock while delivering superior performance.

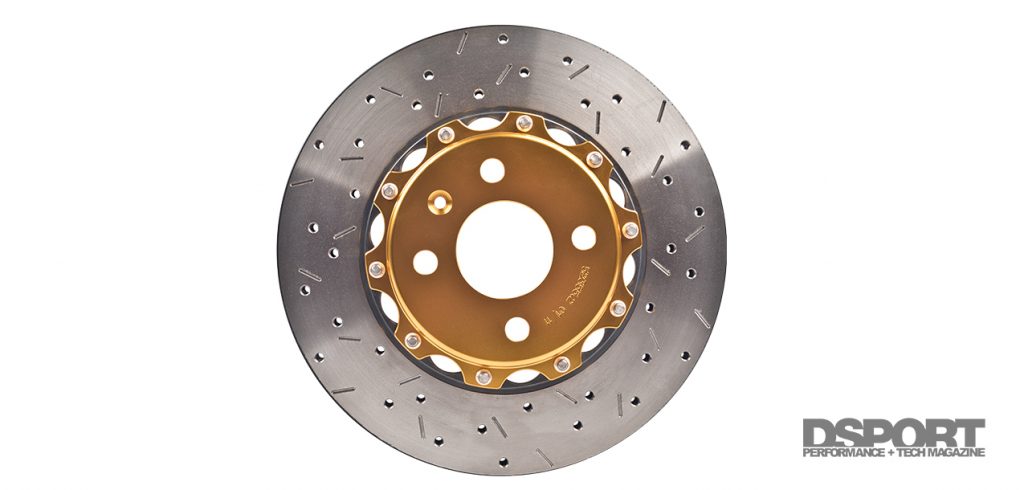

Two-piece brake rotors feature a floating aluminum hat that helps with cooling and weight reduction.

Liquid Stopping Power – Brake Fluid

The first and easiest brake system upgrade is to simply replace the brake fluid with a performance equivalent. Under hard and continuous braking conditions, heat builds up and transfers to the entire braking system, including the fluid. When the brake fluid reaches its boiling point, vaporization occurs. Since vapor is highly compressible, it could negate the force being applied by the fluid and result in unresponsive brakes. Bleeding the brake system and replacing the factory fluid with a higher-performing fluid would help to resist vaporization and maintain braking feel and response.

Improving Feel – Braided Brake Lines

While you’re bleeding the brakes, it could be an opportune time to upgrade your brake lines. The stock lines offer good longevity but might not be as responsive or firm as aftermarket brake lines under the increased pressure of hard braking. This can be attributed to the (typically) rubber lines expanding under pressure. Performance solutions often include a stainless-steel braided sheathing that helps to prevent line expansion and keeps the column of fluid moving from the brake master cylinder to the calipers. As a result, the brake pedal will feel more firm and responsive.

Braided lines help with pedal firmness and response, while the right pads can improve braking performance.

Friction Is Your Friend – Brake Pads

Brakes slow and stop a vehicle by transforming kinetic energy (vehicle in motion) into thermal energy (vehicle slowing or stopping). While the hydraulics of the brake system command the calipers to apply pressure to the brake pads, it’s the brake pads that must generate friction with the rotors to slow the vehicle down. Most factory pads are referred to as “organic” due to the content of the friction material (glass, fiber, rubber, carbon and Kevlar.) This type of pad generally costs less and offers the best balance of cold braking performance, low brake dust production and minimal wear on the rotors. Unfortunately, organic pads tend to have a limited temperature range, wear quickly and will lose their coefficient of friction when overheated. Semi-metallic brake pads (as the name implies) contain metals such as steel, iron and copper. Offered in a variety of compounds designed for different heat ranges, semi-metallic pads help to absorb heat while featuring more aggressive coefficients of friction for improved braking performance. However, the trade-offs of semi-metallic pads include more brake dust, noise, rotor wear and cost. One of the newer types of brake pads are made with ceramic media. Ceramic brake pads bridge the gap between the organic and semi-metallic varieties, offering quieter operation, low dust and a long service life. The drawback is a typically lower coefficient of friction and poor heat conduction. This means that there is less bite when you hit the brakes, especially when they’re cold. It also means that the pad’s resistance to heat absorption leaves the rest of the braking system to handle any additional heat.

Performance brake pad solutions come in a broad variety of pad compounds covering a wide range of operating temperatures. The right pad for your application depends on the type of driving you’re doing. Performance street pads, both semi-metallic and ceramic, typically offer improvements in all categories compared to organic pads, making them ideal for a streetcar. In the case of a track vehicle, where high speeds and heavy braking segments occur frequently, the brakes will be forced to generate even more friction and heat compared to typical street driving. Thus, a good semi-metallic pad with the right heat range would be the best choice. Picking the right heat range is important for proper and safe vehicle operation. A novice driver may not push the car hard enough to get certain pads up to optimal temperature and therefore may experience inferior performance. Similarly, an advanced driver might exceed the heat range (and subsequently be left with no coefficient of friction) in a set of intermediate pads.

Vented rotors feature cooling channels that facilitate heat dissipation. This example also features a slotted rotor surface.

Storing and Dissipating Heat – Brake Rotors

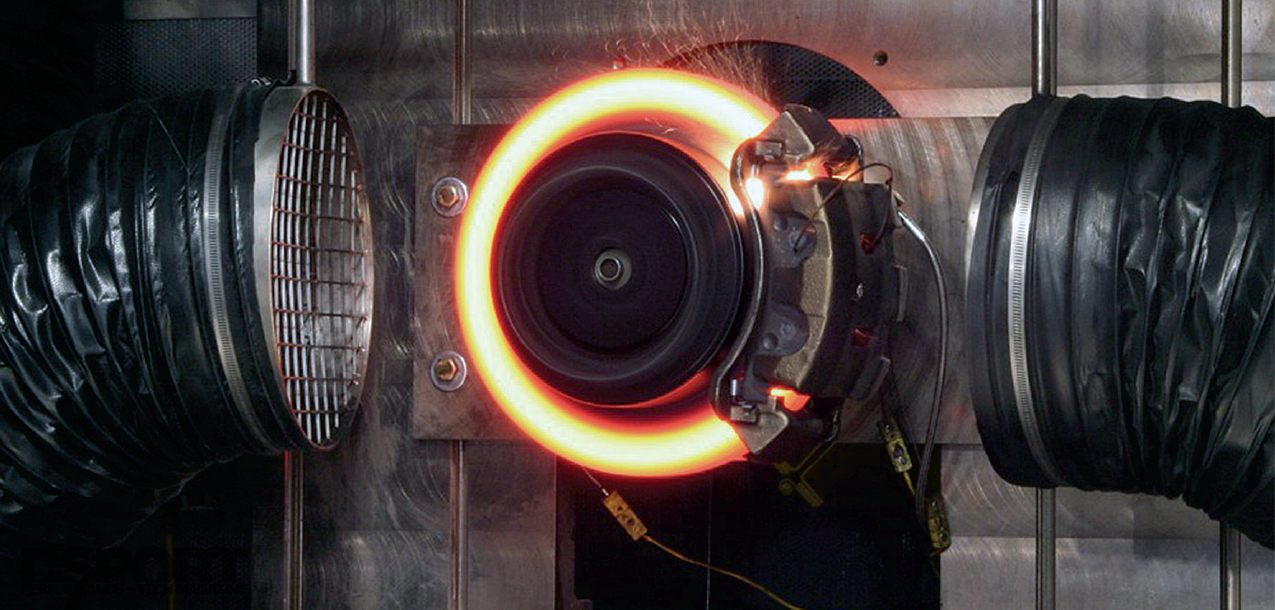

Rotors serve a critical role in the brake system. When the pads clamp down on the rotors, the generated friction heats the rotors as the vehicle is slowed. A good rotor will store heat under braking while cooling down quickly when in motion. Brake rotors are available in two forms, vented and solid. Most front brakes are vented while some rear brake rotors are solid. Higher end vehicles and heavier vehicles tend to be equipped from the factory with vented disc brakes at all four corners. A vented rotor cools more quickly compared to a solid disc, which is an advantageous and desirable trait. Some rotors also feature slotting, cross-drilling or both. These rotor features serve to release the gasses and dust that build up between the rotor and pad under repeated hard braking, ensuring optimal pad-to-rotor contact. Contrary to popular belief, these features were not intended to aid in disc cooling.

Gassing

Under braking, friction between the rotor and pad releases gasses that build up between them. This condition is known as “gassing”. Slotted or cross-drilled rotors help to vent these gasses to ensure consistent braking.

Clamping Down on Speed – Calipers

The final component of the brake system is the brake caliper. The calipers apply hydraulic pressure to the brake pads against the rotors to produce friction. Arguably the most recognized component of a brake system, the brake calipers stand out from behind the spokes of the wheels and exude the braking performance one might expect from a car. As mentioned earlier, most brake calipers (and brake systems) are optimized as a compromise to provide the hydraulic pressure necessary to squeeze the brake pads against the rotors to generate friction for typical street driving. Therefore, calipers come in a variety of sizes and configurations.

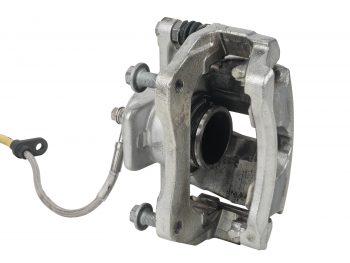

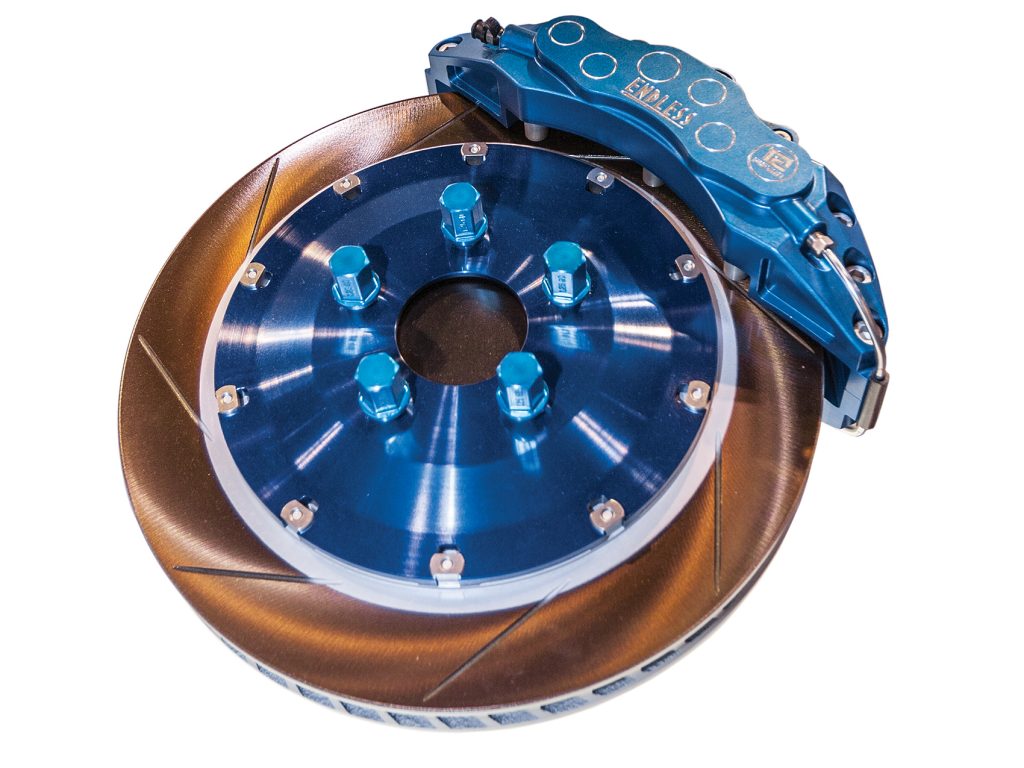

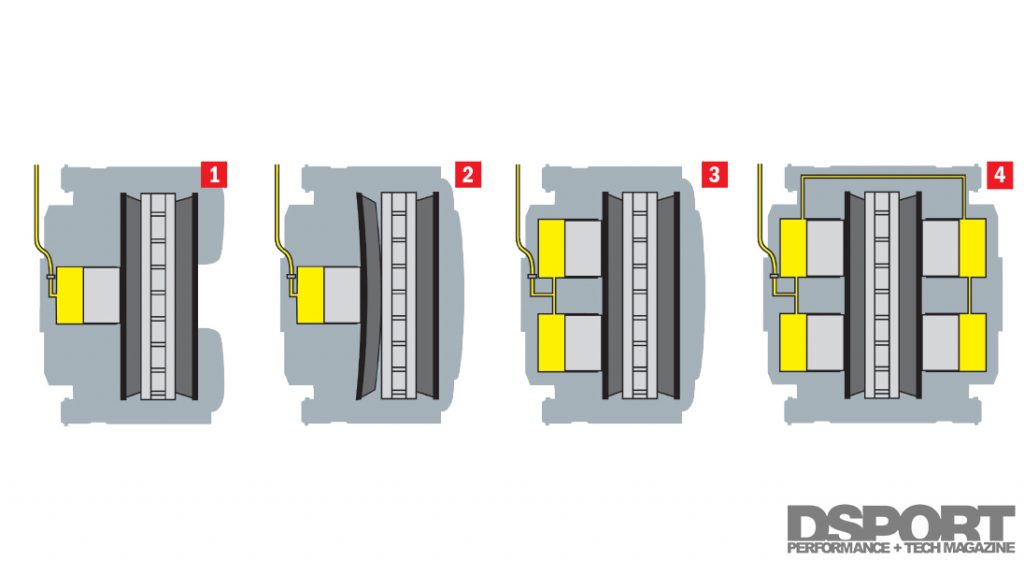

A factory single piston sliding caliper (left) cannot evenly distribute pressure across the entire pad surface as efficiently as an opposed multi-piston caliper (right).

The lightest and most economical solution, the sliding caliper, features either a single- or multi-piston design that slides along a fixed mounting point. The piston(s) apply pressure to one pad, causing the caliper body to slide and pull the other pad against the rotor during braking. If the caliper does not slide evenly, it provides unequal brake pad wear and inadequate hydraulic pressure, especially in aggressive driving or track duty.

By contrast, the fixed brake caliper weighs and costs more than the sliding caliper. However, fixed calipers generally feature an equal number of opposed pistons, ensuring equal pad wear and (in the case of larger calipers) more pad/friction surface area for better stopping performance. However, if one of the pistons gets stuck, unequal pressure will be applied to the pad, causing uneven wear and reduced braking performance.

Single vs. Multiple

Under normal conditions, a single piston sliding caliper (1) applies pressure to both pads evenly. If the caliper does not slide freely under hard braking, uneven pressure is applied to the pad (2) resulting in uneven wear and reduced braking performance. A dual-piston sliding caliper (3) applies even more pressure to the pads more evenly for improved stopping performance. In an opposed, multi-piston caliper (4), a greater amount of pressure can be evenly applied to both brake pads for even greater braking performance and even pad wear.

Upgrades – Master Cylinder & More

In a factory brake system, the brake master cylinder stores the hydraulic brake fluid that is forced through the lines to the calipers. The master cylinder comes sized specifically for the calipers of the vehicle to deliver a specific feel for a given pedal travel. If you decide to upgrade brake calipers (for example, a big brake kit and/or switching from sliding calipers to fixed multi-piston calipers), you might need to upgrade to a larger master cylinder capable of displacing more fluid in order to properly and safely set up the brake system. Should the brakes begin to feel imbalanced, especially after upgrading the front brakes, it may also be necessary to adjust or upgrade the brake proportioning valve to restore balance to the braking system.

More and Bigger Isn’t Always Better

Brakes have become quite the fashion item in the enthusiast market. While bigger rotors and larger calipers offer a visual impact, consider your vehicle, wheel size and purpose when purchasing an upgrade. Better braking is always desirable, but too large a brake rotor and caliper could equate to unnecessary expense if you have to buy larger wheels (for clearance) or additional investments in time and labor to dial in the brake system. Fortunately, significant improvements in braking performance can be had without necessarily needing to change the entire system. If you’re willing to put in the time and effort, superior stopping can be had at the press of the pedal. If you’re carving canyons or going to the track, it’s essential.

Bolt-On Basics | Performance Tuning 101

• Air Intake Systems – The Pathway to More Power

• Exhaust Systems – Uncorking Your Engine’s Potential

• ECU Tuning – Harnessing the Power of Technology

• Fuel Systems – Quench Your Engine’s Thirst

• Forced Induction Systems -Boost for Max Power

• Cooling Systems – Less Heat for Longer Life and More Power