In the 4-stroke symphony performing in your engine bay, when a spark plug misses its cue and doesn’t fire, the results are definitely not harmonious. There is a loss of power and fuel is sent through the engine without ever extracting any of its energy. All of your attempts to get more air and fuel into the combustion chamber will only result in misfiring and a loss of power if you don’t have enough spark to ignite the mixture completely, properly and on time.

Text by Michael Ferrara and Arnold Eugenio // Photos by DSPORT Staff

DSPORT Issue #148

A Spark’s Life

Voltage can be described as a measure of the force required to move electric energy through a conductor. In your ignition system, a high-voltage current is required to allow electricity to travel from the spark plug’s center electrode, through the pressurized fuel/ air mixture, and into the side electrode through an electrical arc.

This is the premise behind how spark plugs work. With enough voltage between the plug’s center electrode and the side electrode, the air gap (which is filled with combustible fuel/air mixture) in your engine will ionize. An electrical charge will be transferred between the two and, in the process, generate enough heat to combust the fuel/air mixture.

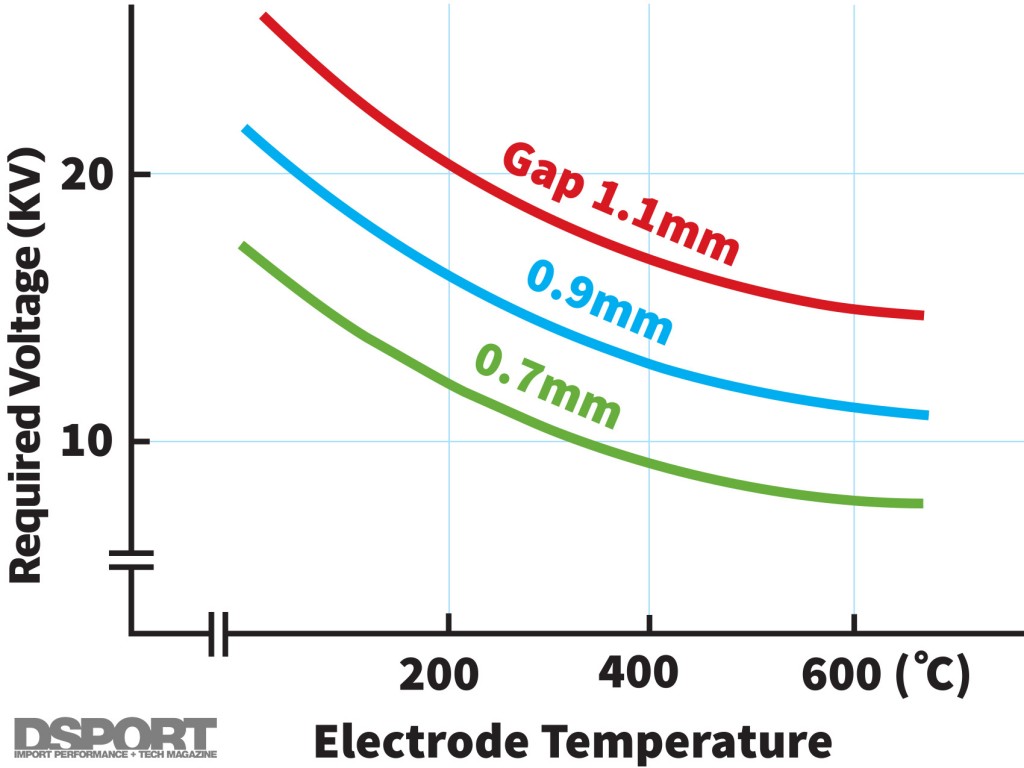

There are three main factors that dictate how much voltage is needed to ionize the air between the plug gap; the size of the gap, the amount of pressure in the cylinder at the time of spark initiation and the diameter of the center electrode. The dynamic factor in that function is the in-cylinder pressure. If the factory ignition system cannot output enough voltage to keep up with increased cylinder pressures, the result is a misfire or “blow out” of the spark.

The first step in ensuring proper ignition system functionality is to make sure your spark plug is gapped correctly. Manufacturers normally provide gap ranges for their plugs that set the distance at an optimum length. A good way to maximize the gap distance would be to widen the gap in increments of .005 inch, checking for misfire after each gap. When misfire occurs, reduce the gap by .005 inches and the plug should be at its peak operating length. At this setting, however, the plugs should be checked regularly to make sure the electrodes don’t erode to the point of creating a gap wider than the maximum-tested setting.

The spark plug’s center electrode diameter also affects the amount of voltage required to produce an adequate spark. Typically, large diameter electrodes are used in order to extend the service life of the spark plug, but these larger diameters require a higher voltage to fire. Some spark plugs are manufactured with expensive metals and alloys such as platinum, nickel, gold palladium and iridium for durability. These materials better resist melting and/or erosion, keeping the center electrode diameter consistent and allowing you to go longer between service replacements of the plugs. The expected diameter consistency allows the plug manufacturer to use a smaller center electrode, allowing for a lower voltage requirement for spark initiation. However, the use of these materials drives up the price of each plug. Additionally, care should be taken to follow manufacturer’s directions for gapping.

| Alloy Comparisons | (Ir) | (Pt) | (Ni) | (Au) | (Ag) |

|---|---|---|---|---|---|

| Melting Point (F) | 4449 | 3216 | 2647 | 1945 | 1760 |

| Strength (Kpsi) | 159 | 20 | 97 | 19 | 19 |

| Electrical Resistance | 2.09 | 4.17 | 2.69 | 0.9 | 0.63 |

| Hardness | 240 | 40 | 160 | 25 | 26 |

–

The amount of in-cylinder pressure also determines how much voltage is needed to properly initiate the spark. The greater the in-cylinder pressure, the harder it is for an electric current to travel through the fuel/air mixture between spark plug electrodes, raising voltage requirements accordingly. Almost every modification done to your engine in the name of power creates increasingly higher-cylinder pressures, making it progressively harder for your ignition system to supply enough voltage to induce ionization. Forced-induction engines can see in-cylinder pressures that are two-to- four times greater than that of a naturally-aspirated engine – keep this in mind when planning ignition system upgrades on an N/A to forced-induction conversion.

Finally as the air/fuel ratio becomes leaner, the voltage required to produce a spark becomes even higher. If the car’s ignition system cannot produce the voltage required to spark a lean air/fuel mixture properly, you may have to richen up the fuel mixture beyond its optimum ratio, preventing you from reaching the optimum power-producing capability of your engine and wasting fuel in the process. It’s in your ability and best interest to change the factors that affect the other parameters as reducing overall power output is not a viable option.