Light Your Fire

Almost all factory ignition systems operate on the principle of the inductive coil. The vehicle’s 12-volt electrical system provides current to one or more ignition coils. The coil uses the energy to create a magnetic field between its primary and secondary windings. When the coil is triggered the magnetic field collapses and a high voltage charge is sent through the coil’s secondary circuit to the spark plug. On systems with a distributor, this energy must first pass from the coil wire to the distributor, where it is then sent through the spark plug wire and finally the spark plug. On distributorless or coil-on-plug systems, each spark plug is assigned its own coil, reducing the distance from coil to plug that the voltage must travel. Inductive ignition systems typically provide a low-to-mid intensity spark with a long burn duration.

Almost all factory ignition systems operate on the principle of the inductive coil. The vehicle’s 12-volt electrical system provides current to one or more ignition coils. The coil uses the energy to create a magnetic field between its primary and secondary windings. When the coil is triggered the magnetic field collapses and a high voltage charge is sent through the coil’s secondary circuit to the spark plug. On systems with a distributor, this energy must first pass from the coil wire to the distributor, where it is then sent through the spark plug wire and finally the spark plug. On distributorless or coil-on-plug systems, each spark plug is assigned its own coil, reducing the distance from coil to plug that the voltage must travel. Inductive ignition systems typically provide a low-to-mid intensity spark with a long burn duration.

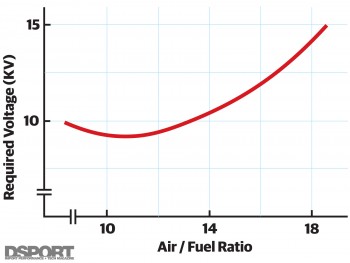

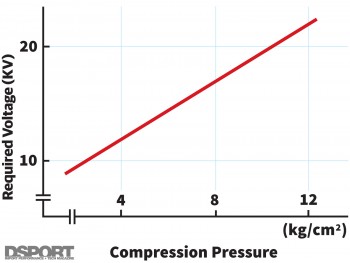

The required voltage to properly ignite the air/fuel mixture within the combustion chamber goes up as the mixture becomes leaner and the cylinder pressure increases.

In order to compensate for increased voltage requirements, the aftermarket provides a number of ignition amplifier solutions, most of which work on the capacitive discharge (CD) principle. These systems store the spark energy in capacitors rather than the ignition coil itself allowing the ignition system to provide additional spark energy. Some of these systems “fire” multiple times to ensure ignition of typically-lean fuel/air mixtures found at idle and low-RPM cruising. This is due to the CD ignition system’s tendency to produce ultra-high intensity sparks for shorter durations of time. These types of systems increase firing frequency per power stroke to compensate for a shorter spark life.

Ignition amplifiers supplement coil-on-plug ignition systems to ensure adequate spark energy is delivered to the combustion chambers.

If your vehicle has a distributor, you can use any single-channel aftermarket amplifier coupled with your coil of choice. If the factory coil isn’t expected to be able to deliver the additional voltage required by your high-cylinder pressure or high-boost application, a number of aftermarket coils are available. On some older applications, converting an internal coil (where the coil is mounted inside the distributor housing) to an external coil setup affords access to a wider range of coil upgrades.

–

For wasted-spark, direct-fire or coil-on-plug systems, you will need to run a multi-channel ignition amplifier should you wish to upgrade. Additionally, some manufacturers offer higher-quality individual coil packs for these multi-coil systems.

Recent years have seen a small resurgence in plasma ignition technology. Plasma technology produces a different spark profile than that created by a traditional spark plug. With plasma ignitions, the majority of the energy is loaded to the beginning of the spark event stored in the capacitor circuit. The result is a super-high- intensity discharge that has the same overall duration as the primary ignition system in use (inductive or capacitive-discharge).

One version of plasma ignition technology places the plasma technology directly into the plug to ensure compatibility with any type of ignition system (distributor, wasted spark or coil-on-plug.) We have tested this technology with great success. Since the plasma technology is built into the plug itself and affects the quality of the spark, these systems can still theoretically benefit from the addition of an ignition amplifier and coil to help provide the required voltage to initiate the spark event.