The design of the cylinder head (intake & exhaust port size length and shape; valve angle, valve size, number of valves per cylinder) plays an important role. The design determines the velocity and volume (CFM) of air-and-fuel entering and exhaust gasses exiting the combustion chamber. While the proper selection of camshafts can optimize the performance for a given cylinder head and short-block combination, there are a number of processes that can be performed to the cylinder head to improve performance and reliability. The valvetrain can be upgraded to endure higher engine speeds while larger valves and porting can improve air flow through the cylinder head.

Staff Report // Photos By Michael Ferrara and Richard Fong

In the last installment for my KA24DE, the bottom-end was blueprinted and carefully assembled to endure the punishment of forced induction. With the bottom-end fortified, it was time to improve the top- end of the engine.

The Work Order

• Disassembly of Head

• Clean & Inspect

• Resurface Head

• Install Bronze Valve Guides

• Cylinder Head Porting

• Performance Valve Job

• Install +1mm IN/EX Valves

• Install High-Rate Springs

• Convert to Shim Under Bucket

• Install Titanium Retainers

• Set Valve Lash

• Flow Bench Test

Port Flow Design

We sent our KA24DE cylinder head to Tom Fujita at Port Flow Design. Port Flow Design would be putting this head through a number of processes to ready it for our KA24DE contender. In the end, our used KA24DE head would be upgraded to provide improved flow and higher-RPM potential than it ever could produce when new.

Tom Fujita of Port Flow Design polishing the chambers of a Honda B-series cylinder head.

Cleaning, Inspection & Repairs

The KA24DE head was stripped bare and cleaned before inspection. Since we started with a used head, the condition of the guides, seats and surface must all be checked. In our case, the guides were marginal so we replaced them with high-performance bronze guides. Since we would be installing oversized (+1mm) stainless-steel intake and Inconel exhaust valves from Supertech, there was no need to inspect the original valves. Of course, if the stock valves are to be reused, they must be inspected and reconditioned. We also learned that the valve seats were in good shape so now the head was ready for the next stage.

Porting & Chamber Work

The porting process involves the reshaping of the intake and exhaust ports to increase the volumetric flow (measured in cubic-feet-per-minute or CFM). Ideally, improvements can be made to the volumetric flow without significantly reducing the velocity through the ports. During the porting process, careful attention is paid to the transition area from the intake opening to the bowl area. Removing too much material or removing material from the wrong areas kills airflow velocities and performance. When larger valves are being used, it’s important to make sure that the porting is optimized for the larger valves. With larger valves, the combustion chamber is often reshaped to help unshroud the valves.

The porting process involves the reshaping of the intake and exhaust ports to increase the volumetric flow (measured in cubic-feet-per-minute or CFM). Ideally, improvements can be made to the volumetric flow without significantly reducing the velocity through the ports. During the porting process, careful attention is paid to the transition area from the intake opening to the bowl area. Removing too much material or removing material from the wrong areas kills airflow velocities and performance. When larger valves are being used, it’s important to make sure that the porting is optimized for the larger valves. With larger valves, the combustion chamber is often reshaped to help unshroud the valves.

Valve Job

Port Flow Design performs both multi-angle and full-radius valve jobs. The design and quality of the valve job will influence performance and longevity. A quality valve job must provide a good transition for the air to pass between the valve and valve seat once the valve is lifted. The valve job must also produce an airtight seal between the valve and seat when closed. The amount of contact area between the valve seat and valve must be adequate to provide heat transfer from the valve head to the valve seat.

The Valvetrain

Higher-rate valve springs are often needed with the more aggressive ramp profiles of aftermarket camshafts. Titanium retainers and a shim-under-bucket from Supertech help to reduce the weight of the valvetrain. Lowering the valvetrain’s weight makes it easier to control at higher engine speeds.

Tom Fujita of Port Flow Design tested the flow of the KA24DE cylinder head before and after porting on the Superflow SF-600 flow bench.

We Have Lift Off

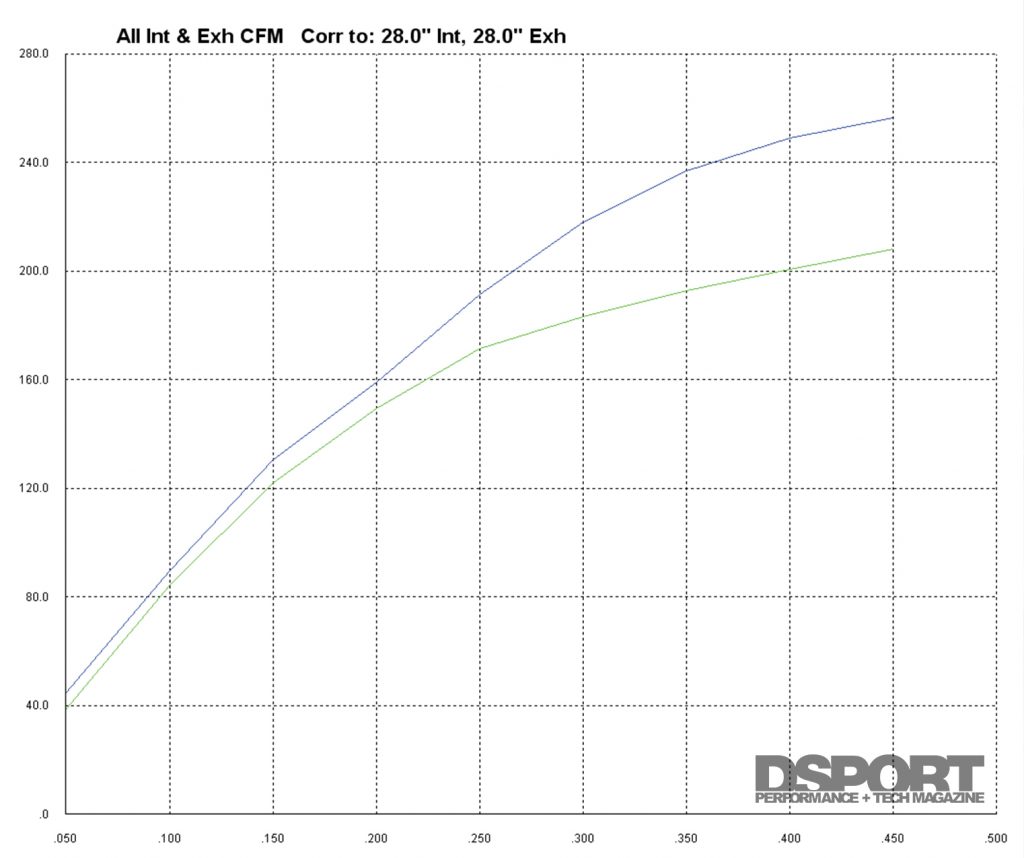

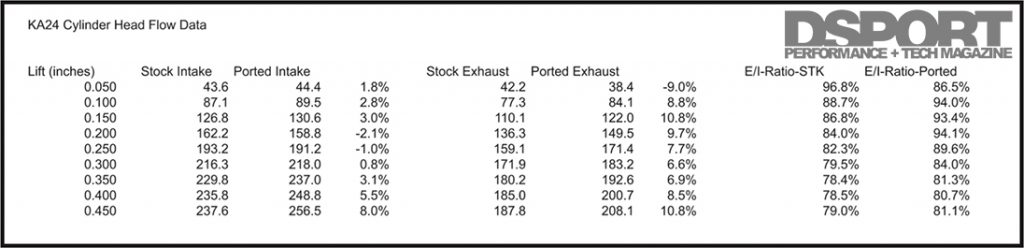

Port Flow Design “flowed” the finished cylinder head on the Superflow SF-600 flow bench to analyze the gains versus stock. The Port Flow head showed gains of 8.0-percent on the intake and 10.8-percent on the exhaust at .450-inch of valve lift. As soon as the SR20DET cylinder head is complete, we’ll flow it on the same test bench for an apples-to-apples comparison. Stay tuned.

Follow the KA24 vs SR20 Battle

1) SR20DET vs KA24DE | Which is Nissan’s Best Four Cylinder?

2) D’Garage Silvia | Preparing For the KA vs SR Battle

3) KA24DE vs SR20DET Act II | Preparing the KA for Boost

4) KA24DE vs SR20DET Act III | SR20DET Heads Up

5) KA24DE vs SR20DET Act IV | Port Flow Design Readies our KA24DE Head

6) KA vs. SR Battle: Act V | International SR23 – Built Right And Ready To Fight

7) SR20 Steps Forward, KA24 Gets Knocked Back | KA vs SR Update