There’s a reason why enthusiasts choose aftermarket air intakes as one of the first performance modifications. Not only are most intake systems fairly straightforward to understand and easy to install, they typically yield substantial power gains as well. With that said, don’t let air intakes’ apparent simplicity fool you. Aftermarket intakes require extensive knowledge and engineering to design and build.

By Sami Sharaf

Stock OEM Parts

Traditionally, original equipment manufacturers (OEM) address three essential categories in the design of a vehicle’s air intake system. First, a factory intake system must lend itself to extended service intervals. As such, filters need to deliver good filtration and they need to do so for a long time before needing replacement. Second, the OEMs keep a watchful eye (and ear) on the noise levels emitted from the intake system. If an intake makes more power but generates increased noise, it will not be approved for production. Lastly, factory intake systems need to be constructed under very cost-effective methods with inexpensive materials. This means that an intake design costing the least amount of money is more likely to go into production than a better performing system that costs more. While performance enthusiasts couldn’t care less about these criteria, it’s what most cars come equipped with from the factory.

Performance conical air filters are available with either dry or oiled filter media, both can deliver exceptional filtration of fine particles.

Changing Times

In the early days of air intake design and production, a high-power yielding intake system was relatively easy to design for two reasons. First, many of the popular vehicles used speed-density based fuel injection systems. These vehicles didn’t rely on picky mass air flow (MAF) metering that demanded specific flow profiles for the ECU to know how much fuel to deliver. With these types of vehicles, an engineer would simply need to provide peak flow by minimizing or eliminating restrictions in the inlet tract. On mass air flow metering setups, the dedicated MAF sensor housing would often need to be reused with the aftermarket filter and tubing. The other reason that intakes were easy to design in the past has to do with the focus of the OEM engineers. OEMs didn’t spend much time engineering factory air intakes to produce peak power. But today’s lean vehicles run more efficiently and that means performance needs to be extracted wherever possible. Simply put, OEMs left more power for the aftermarket to tap into back in the day.

Modern Issues

With OEMs carving out as much power as possible (within their strict guidelines) and more vehicles utilizing mass air flow metering, building air intake systems with appreciable performance gains are becoming increasingly challenging and involved. A critical component of modern intake design lies in the mass-air signal to the ECU. When an intake system tweaks the signal or positions the sensor in such a way that the ECU receives a lower reading than factory, the ECU will deliver less fuel and subsequently advance the ignition timing. Readings higher than the factory signal will cause the opposite to occur. Both scenarios may increase performance but more often than not, going too far in one direction will result in decreased performance, less than optimal air-fuel ratios, compromised fuel economy and the possibility of engine-damaging detonation.

Intaking More Power

When considering air intake systems for internal combustion engines, additional performance can be achieved through at least five different strategies. The majority of air intake systems available today will employ a combination of these methods to maximize a specific engine’s performance. Almost all aftermarket intake systems reduce the inlet restriction by using a high-flow (low-restriction) filter element. These elements allow the engine to ingest air easier and will generally have additional filter surface area to provide increased filtration over the factory element. Second, aftermarket units can offer a bump in power if the inlet air temperature is decreased. As a general rule of thumb, every 11 degrees of temperature drop corresponds to a one-percent increase in horsepower. The third tactic involves an increase in the diameter of the air intake pipe between the filter and the throttle body. This allows more air to be available for the engine to ingest into the cylinders during the intake stroke of combustion. The fourth and now one of the more popular methods is the modification of the mass air flow signal to the ECU (for vehicles with MAF sensors). Amplifying the signal will result in an increase of fuel, while a decreased signal will result in less fuel being injected into the engine. Another “tuning” strategy involves maximizing airflow at specific engine speeds. This technique is often achieved by varying the combination of pipe diameters, number of bends and the length of the tubing. Using some or all of these methods can deliver an air intake system that is well matched for the specific engine it is intended for.

Filtering Options

One of the key elements to air intake systems is the air filter itself. Some air intake manufacturers use oiled filters while others use dry filters. Oiled performance filters are constructed from high-flowing cotton media that is treated with oil to capture particles before reaching the intake tract. These filters are said to deliver less restrictive and more efficient airflow. While these filters can be cleaned, they require that oil be reapplied after cleaning. Aside from oiled cotton filters, the other option is a dry air filter that is made from synthetic materials. Usually, dry synthetic air filters deliver extremely fine filtration while still providing a restriction-free pathway to the intake tract. Both styles of air filters can deliver great performance and longevity if used and serviced properly.

Performance panel filters are the perfect upgrade when it comes time to replace the OEM air filter.

All Shapes and Sizes

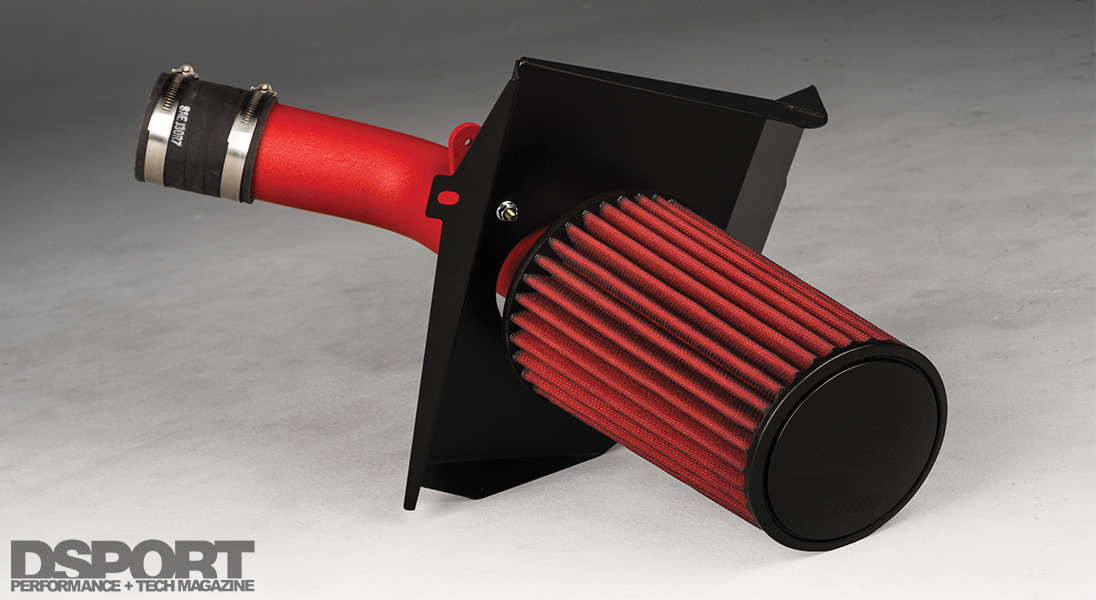

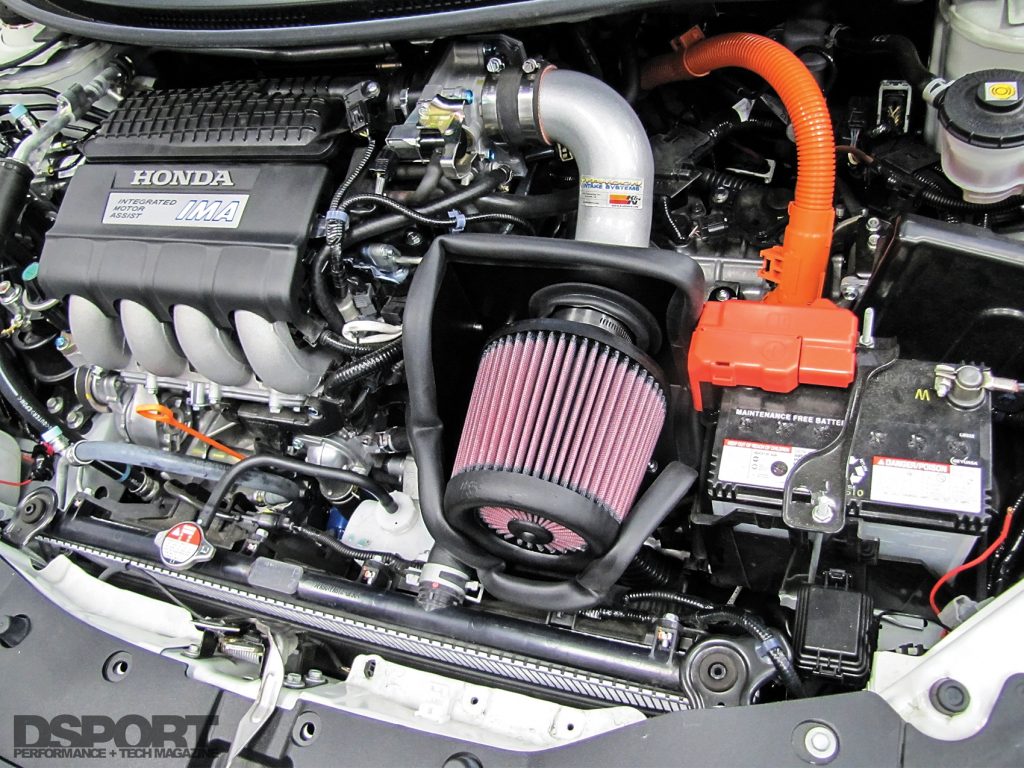

The least complex air intake upgrade can usually be found in the form of a drop-in replacement panel filter. These performance filters act as direct replacements to the factory filter media but can offer justifiable improvements in performance at a low cost. Typically, these filters are constructed from high-flowing media, which creates a less restrictive pathway to the inlet tract. Routine maintenance is an ideal opportunity to upgrade your air intake system with a performance drop-in air filter instead of another factory offering. For additional power increases, short-ram intakes can generally excel over drop-in replacement filters and even other intake designs on the dyno. These intakes can be straightforward in their layout, which leads to a simple installation. Short-ram systems typically feature a conical air filter near the factory location with a rigid aluminum pipe connecting the throttle body to the filter. In some cases, manufacturers will construct a heatshield or induction box for the air filter to reside in. This allows short-ram intakes to draw in air that is cooler than the ambient temperature of the engine compartment. The most complex air intake systems are often cold-air intake systems that position the inlet to draw in the coolest air available. This space is typically low in the engine compartment or just outside of the engine compartment within the front bumper cover. While some cold-air intakes may produce slightly less power on the dyno, they are known to deliver better overall performance in real-world driving conditions when compared to short-ram intakes. Most of the time, the added complexity and extra installation steps are worthwhile for the performance gains afforded by cold-air systems.

The least complex air intake upgrade can usually be found in the form of a drop-in replacement panel filter. These performance filters act as direct replacements to the factory filter media but can offer justifiable improvements in performance at a low cost. Typically, these filters are constructed from high-flowing media, which creates a less restrictive pathway to the inlet tract. Routine maintenance is an ideal opportunity to upgrade your air intake system with a performance drop-in air filter instead of another factory offering. For additional power increases, short-ram intakes can generally excel over drop-in replacement filters and even other intake designs on the dyno. These intakes can be straightforward in their layout, which leads to a simple installation. Short-ram systems typically feature a conical air filter near the factory location with a rigid aluminum pipe connecting the throttle body to the filter. In some cases, manufacturers will construct a heatshield or induction box for the air filter to reside in. This allows short-ram intakes to draw in air that is cooler than the ambient temperature of the engine compartment. The most complex air intake systems are often cold-air intake systems that position the inlet to draw in the coolest air available. This space is typically low in the engine compartment or just outside of the engine compartment within the front bumper cover. While some cold-air intakes may produce slightly less power on the dyno, they are known to deliver better overall performance in real-world driving conditions when compared to short-ram intakes. Most of the time, the added complexity and extra installation steps are worthwhile for the performance gains afforded by cold-air systems.

Buyer Beware

To find the best air intake system for your specific vehicle, we suggest utilizing the information in this article along with recommendations from the top tuners for your specific vehicle platform. Keep in mind that Company A may provide the best performance on one application while Company B may offer a better system for a different application. Once you do your research, you’ll find that there are numerous companies that offer high-quality air intake system solutions. By the same token, an even greater number of companies offer low-quality systems that aren’t designed with any engineering basis. Once you find the perfect intake system for your car, you’ll be well on your way to more power.

Bolt-On Basics | Air Intake Systems PDF

DSPORT Product Highlight:

Air Intake Systems

Cobb Tuning

Part # 715315

MSRP: $335.00

Cobb’s SF Intake and Airbox (P/N 715315) for the 2015+ Subaru STI combines the design of a short ram and cold air intake, providing dense air to the engine. With a conical air filter leading into the velocity stack, the intake is built from composite materials.

AEM Induction Systems

Part# 21-754DS

MSRP: $375.00

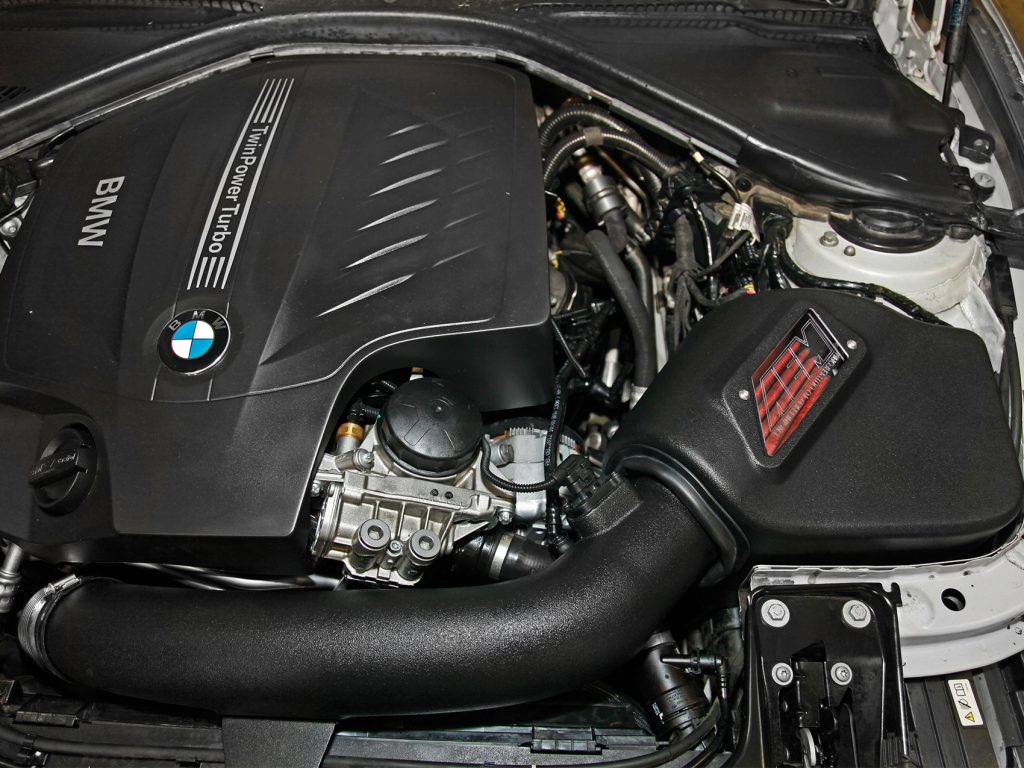

The AEM Cold Air Intake System (P/N 21-754DS) for BMW 335i and M235i features an open bottom airbox for maximum airflow. Constructed from roto-molded polyethylene, the intake tube and airbox is designed for minimum air restriction to the engine. AEM estimates a gain of 12 horsepower.

Racing Beat

Part # 18299

MSRP: $368.00

The Racing Beat RX-8 REVi Intake (P/N 18299) is a CARB-exempt, direct bolt-on intake kit for the 2004-2011 Mazda RX-8. Featuring a K&N cone filter, the intake kit is designed to improve performance without sacrificing drivability. The kit can be supplemented with the Racing Beat Ram Air Duct to improve intake temperatures.

K&N Engineering

Part # 69-8008TTK

MSRP: $599.00

The K&N Typhoon Air Intake System for 2014-2015 Subaru Impreza (P/N 69-8008TTK) features a free-flowing aluminum tube design to improve throttle response and engine sound. The system, which can last up to 100,000 miles before servicing, can be installed in around 90 minutes.

Bolt-On Basics | Performance Tuning 101

• Air Intake Systems – The Pathway to More Power

• Exhaust Systems – Uncorking Your Engine’s Potential

• ECU Tuning – Harnessing the Power of Technology

• Fuel Systems – Quench Your Engine’s Thirst

• Forced Induction Systems -Boost for Max Power

• Cooling Systems – Less Heat for Longer Life and More Power