While DSPORT may have shifted focus away from Honda performance over the past few years, we recently had a great opportunity to get back into it. Along the way, we’ll break down the proper way to build a 1,000+ horsepower B-series engine and 8-second capable Civic.

Text by Michael Ferrara // Photos by Jun Chen

Combat Veteran

[pullquote]TO SAY THAT THE BUILD INVOLVED A LOT OF ‘MONKEY SEE, MONKEY DO’ WOULD BE AN UNDERSTATEMENT[/pullquote]Five years ago, our former employee Shannon Stanciel joined the U.S. Army and took off to Afghanistan to fight terrorism. His main priority was to come home alive and intact from his tour of duty. If he was able to do that, his plan was to build an 8-second Honda Civic upon his return. Shannon returned from his last tour of duty while DSPORT was relocating to its new facility. As such, DSPORT wasn’t able to take on the project as soon as Shannon returned. Since Shannon had a pent up desire to go racing, he put together the car himself, based on information provided by Internet research, forums, local gurus and other racers. To say that the build involved a lot of “monkey see, monkey do” would be an understatement. After a year of swapping across a number of different turbocharger and camshaft combinations, Shannon eventually built a Civic that could run 9.3s in the quarter mile.

Little Help, Lot of Hurt

Assuming that Shannon had a reliable and solid combination that just needed some fine tuning, we were finally in a position to offer some help. Shannon had been very interested in Skunk2’s modular intake manifold. We figured that an article on dyno testing the manifold on Shannon’s engine would be a win-win for everyone. We’d get the scoop on the performance potential of the manifold and Shannon would hopefully gain some more power to chisel away at the 3/10ths of a second that he needed to find.

Assuming that Shannon had a reliable and solid combination that just needed some fine tuning, we were finally in a position to offer some help. Shannon had been very interested in Skunk2’s modular intake manifold. We figured that an article on dyno testing the manifold on Shannon’s engine would be a win-win for everyone. We’d get the scoop on the performance potential of the manifold and Shannon would hopefully gain some more power to chisel away at the 3/10ths of a second that he needed to find.

[pullquote]THE ENGINE DROPPED AN INTAKE VALVE AT 10,600 RPM[/pullquote]After the studio shoot of the Skunk2 intake manifold was completed, Shannon dropped off the car at DSPORT. The original plan was to baseline the Civic, then swap over to the Skunk2 manifold with its different plenum spacers. Shannon let us know that he forgot to set the rev limiter and asked us to be sure to only take the engine to 9,500 RPM on the dyno. Jeren apparently had trouble estimating where 9,500 RPM appeared on the 9,000 RPM factory tachometer. Something happened that kept Jeren’s foot on the throttle until the engine went to 11,000 RPM (see sidebar). Unfortunately, the engine dropped an intake valve at 10,600 RPM and proceeded to scrap the pistons, cylinder head and turbocharger in the process.

The Postmortem

Any engine build should begin with an assessment of the engine being replaced or rebuilt. In the case of Shannon’s B18C1, we were unsure of what could be salvaged. After visual inspection, it seemed as though the block was salvageable (just needing proper machine work) and that the rods and crankshaft were candidates to be reconditioned. Unfortunately, a measurement of the crankshaft told a different story. The crankshaft was bent showing 0.0023″ of runout. Honda calls for a maximum of 0.001″ of runout on new cranks (service limit of under 0.002″).[pullquote]ON THIS HONDA ENGINE, WE COULDN’T FIND ONE BEARING… WITH ADEQUATE CLEARANCE[/pullquote] Having a runout of less than 0.001″ (one thousandths) should be the target for any performance build. In fact, keeping runout to half of that value is even better for extending main bearing life. As far as proper bearing clearances on this Honda engine, we couldn’t find one bearing on the engine with adequate clearance. They were all too small and metal-to-metal contact was occurring. The irony was that the engine builder told Shannon that the clearances were set up on the loose side. The builder recommended that Shannon use a 20W-50 oil as a result of the “loose” clearances.

Any engine build should begin with an assessment of the engine being replaced or rebuilt. In the case of Shannon’s B18C1, we were unsure of what could be salvaged. After visual inspection, it seemed as though the block was salvageable (just needing proper machine work) and that the rods and crankshaft were candidates to be reconditioned. Unfortunately, a measurement of the crankshaft told a different story. The crankshaft was bent showing 0.0023″ of runout. Honda calls for a maximum of 0.001″ of runout on new cranks (service limit of under 0.002″).[pullquote]ON THIS HONDA ENGINE, WE COULDN’T FIND ONE BEARING… WITH ADEQUATE CLEARANCE[/pullquote] Having a runout of less than 0.001″ (one thousandths) should be the target for any performance build. In fact, keeping runout to half of that value is even better for extending main bearing life. As far as proper bearing clearances on this Honda engine, we couldn’t find one bearing on the engine with adequate clearance. They were all too small and metal-to-metal contact was occurring. The irony was that the engine builder told Shannon that the clearances were set up on the loose side. The builder recommended that Shannon use a 20W-50 oil as a result of the “loose” clearances.

The Gameplan

After seeing that nothing had been done to “proper” standards on the original engine, we spent extra time checking everything. We assumed nothing was right and measured everything we could get a bore gauge into or a caliper around. In the end, it appeared that the sleeving had likely been properly done. While some damage occurred to the 84mm cylinders, there was nothing that wouldn’t cleanup at an 84.5mm overbore. We would order new pistons, new rods and find a good crankshaft to get it done.

After seeing that nothing had been done to “proper” standards on the original engine, we spent extra time checking everything. We assumed nothing was right and measured everything we could get a bore gauge into or a caliper around. In the end, it appeared that the sleeving had likely been properly done. While some damage occurred to the 84mm cylinders, there was nothing that wouldn’t cleanup at an 84.5mm overbore. We would order new pistons, new rods and find a good crankshaft to get it done.

Cranky Cranks

Thinking it would be easy to find another GS-R crankshaft that was ready to run, Shannon called friends, checked shops and looked at forums to locate what ended up being a total of three different used GS-R cranks. After measuring each, NONE of these crankshafts were useable. Two of the crankshafts had runout above 0.0016″ and the third had a rod journal that was already ground once and damaged. Since no one in the aftermarket offers a B-series crankshaft in the GS-R stroke length, we looked for a solution in the LS stroke length (89mm).

SCAT Solution

Fortunately, SCAT had its 4340 forged-steel 89mm B-series crankshaft in stock and ready to go. The finished crankshaft held its tolerances very well. The runout was less than four-tenths of a thousandth (<0.0004″) and all of the journals were taper-free and within two-tenths of a thousandth (<0.0002″) of each other. Balance was to 0.5 grams. Out of the box, the crank required no prep for its future 1000+ horsepower duty.

Fortunately, SCAT had its 4340 forged-steel 89mm B-series crankshaft in stock and ready to go. The finished crankshaft held its tolerances very well. The runout was less than four-tenths of a thousandth (<0.0004″) and all of the journals were taper-free and within two-tenths of a thousandth (<0.0002″) of each other. Balance was to 0.5 grams. Out of the box, the crank required no prep for its future 1000+ horsepower duty.

CP Carrillo

The original Arias pistons were turned to scrap by the dropped valve. The Eagle rods survived and could have been reconditioned. However, these rods were for a GS-R crankshaft, hence they were 1mm too long and 2mm too thin on the big end width. We opted for an off-the-shelf solution from CP Pistons and Carrillo.

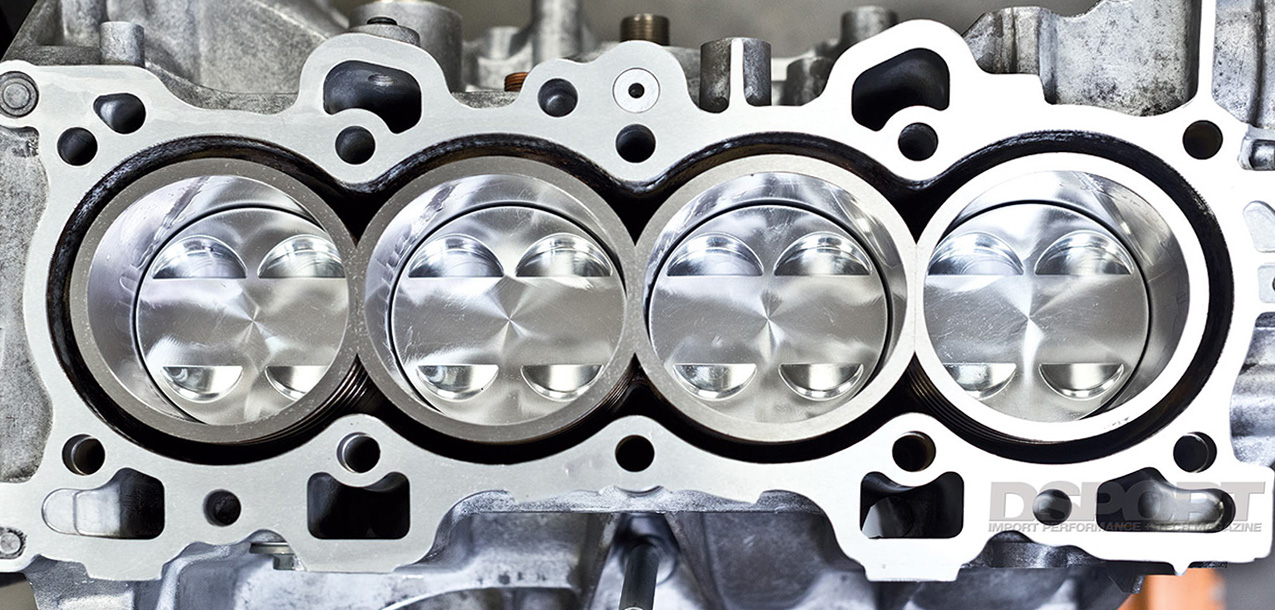

CP Pistons offers a flat-top piston for sleeved B18 engines with an 84.50mm bore. These 2618-alloy slugs deliver a compression ratio in the neighborhood of 10.0:1 when used with a B16A cylinder head (We’ll calculate our exact compression ratio in part two).

CP Pistons offers a flat-top piston for sleeved B18 engines with an 84.50mm bore. These 2618-alloy slugs deliver a compression ratio in the neighborhood of 10.0:1 when used with a B16A cylinder head (We’ll calculate our exact compression ratio in part two).

As for the rod, Carrillo offers the 137mm length rod with the wider 24mm big end width in its PRO-H series. We selected the part number equipped with the CARR 3/8-inch rod bolts for maximum reliability. The CARR bolt upgrade allows for multiple disassembles and re-torquing of the rod bolts without a change in bolt tension.

As for the rod, Carrillo offers the 137mm length rod with the wider 24mm big end width in its PRO-H series. We selected the part number equipped with the CARR 3/8-inch rod bolts for maximum reliability. The CARR bolt upgrade allows for multiple disassembles and re-torquing of the rod bolts without a change in bolt tension.

On any boosted engine build, a secure head gasket seal is a must. A great seal between the engine and cylinder head requires proper surface finishing of the head and the block, the right head gasket and a set of head studs that can provide the necessary clamping force. Today’s multi-layer-steel (MLS) gaskets provide exceptional sealing when and only when the surface finish of the engine block and cylinder head measures to a very low roughness or Ra value. OEMs use the latest machines and techniques to achieve these finishes. [pullquote]MOST MACHINE SHOPS DO NOT HAVE THE EQUIPMENT OR TECHNIQUE TO ACHIEVE THE NECESSARY FINISH[/pullquote]Unfortunately, most machine shops, especially those that mainly work on domestic V8s, do not have the equipment or technique to achieve the necessary finish. As a result, these machine shops deck the surface to a finish that is too rough to properly seal with an MLS gasket. To avoid this situation, it’s best to seek out a machine shop that can surface grind or lap your cylinder head and engine block’s deck surface to the lowest Ra value they can achieve. A surface roughness measured at or below a Ra value of 30 is a must. However, the lower the number, the better the finish and sealing ability of the surface. For instance, the factory finish on most of today’s factory turbocharged aluminum block engines are in the Ra range of 10 to 15 from the factory. Lapping is usually required to get single-digit Ra values.

On any boosted engine build, a secure head gasket seal is a must. A great seal between the engine and cylinder head requires proper surface finishing of the head and the block, the right head gasket and a set of head studs that can provide the necessary clamping force. Today’s multi-layer-steel (MLS) gaskets provide exceptional sealing when and only when the surface finish of the engine block and cylinder head measures to a very low roughness or Ra value. OEMs use the latest machines and techniques to achieve these finishes. [pullquote]MOST MACHINE SHOPS DO NOT HAVE THE EQUIPMENT OR TECHNIQUE TO ACHIEVE THE NECESSARY FINISH[/pullquote]Unfortunately, most machine shops, especially those that mainly work on domestic V8s, do not have the equipment or technique to achieve the necessary finish. As a result, these machine shops deck the surface to a finish that is too rough to properly seal with an MLS gasket. To avoid this situation, it’s best to seek out a machine shop that can surface grind or lap your cylinder head and engine block’s deck surface to the lowest Ra value they can achieve. A surface roughness measured at or below a Ra value of 30 is a must. However, the lower the number, the better the finish and sealing ability of the surface. For instance, the factory finish on most of today’s factory turbocharged aluminum block engines are in the Ra range of 10 to 15 from the factory. Lapping is usually required to get single-digit Ra values.

OEM and premium aftermarket head gaskets are required to get the optimum combustion chamber seal. For this 84.5mm bore size, Golden Eagle offers a factory gasket cut off for the larger bore size. These gaskets are perfect for applications requiring an exceptional seal at extreme cylinder pressures. Of course, keeping the head clamped to the block is no easy task. However, ARP head-studs torqued to the 80-to-90 lb-ft range have proven to get the job done on the Honda B-series engines making quad-digit power figures.

Get in Line

With a flat and surfaced cylinder deck surface, it’s time to line hone the block. By line honing the mains on the block, a number of tasks are accomplished. First, a precision line hone can reduce the taper in the main journal bores. By reducing the taper, the oil film thickness and bearing clearance remains more consistent across the bearing load surface. Second, the line honing process can help to equalize the main journal diameters from journal to journal. When combined with a crankshaft that also has consistency across its main pin diameters, like-sized bearings can be used. For those choosing to use aftermarket bearings, this is a big plus as many aftermarket bearing companies do not offer multiple bearings to get an exact fitment. Third, having consistency in main journal diameters equalizes the amount of crush on the bearings. Having adequate crush provides maximum concentricity in the bearing shells. Finally, the line hone process literally lines up the main journals on the same line. This helps to ensure that the crank’s main pins all center to the block’s main journals. The end result is reduced friction and increased bearing life.

With a flat and surfaced cylinder deck surface, it’s time to line hone the block. By line honing the mains on the block, a number of tasks are accomplished. First, a precision line hone can reduce the taper in the main journal bores. By reducing the taper, the oil film thickness and bearing clearance remains more consistent across the bearing load surface. Second, the line honing process can help to equalize the main journal diameters from journal to journal. When combined with a crankshaft that also has consistency across its main pin diameters, like-sized bearings can be used. For those choosing to use aftermarket bearings, this is a big plus as many aftermarket bearing companies do not offer multiple bearings to get an exact fitment. Third, having consistency in main journal diameters equalizes the amount of crush on the bearings. Having adequate crush provides maximum concentricity in the bearing shells. Finally, the line hone process literally lines up the main journals on the same line. This helps to ensure that the crank’s main pins all center to the block’s main journals. The end result is reduced friction and increased bearing life.

Honing a Perfect Circle

One of the most critical machining operations involves the precise honing of the cylinders. This operation should accomplish the following: 1) remove taper from the cylinder; 2) establish roundness in the cylinder, 3) set the proper amount of piston-to-cylinder-wall clearance and 4) finish the surface of the cylinder to deliver long cylinder life, proper lubrication, minimal friction, fast engine break-in and superior ring seal. While unicorns or a block that doesn’t benefit from a torque-plate during honing may exist, we have yet to find either. The Honda B-series with factory or aftermarket sleeves is no exception. Despite our block having a set of massive, ductile-iron sleeves in place, our measuring found that the block distorts significantly (over 1.3 thousandths) when the cylinder head (or a torque plate) is bolted in place.

One of the most critical machining operations involves the precise honing of the cylinders. This operation should accomplish the following: 1) remove taper from the cylinder; 2) establish roundness in the cylinder, 3) set the proper amount of piston-to-cylinder-wall clearance and 4) finish the surface of the cylinder to deliver long cylinder life, proper lubrication, minimal friction, fast engine break-in and superior ring seal. While unicorns or a block that doesn’t benefit from a torque-plate during honing may exist, we have yet to find either. The Honda B-series with factory or aftermarket sleeves is no exception. Despite our block having a set of massive, ductile-iron sleeves in place, our measuring found that the block distorts significantly (over 1.3 thousandths) when the cylinder head (or a torque plate) is bolted in place.

To ensure that the cylinders were as round and taper free as possible by the end of the honing process, we bolted a BHJ Products torque plate to the block with a Golden Eagle 84.5mm head gasket and ARP head studs torqued to 85 lb-ft with ARP Ultra-Torque assembly lube. After the torque plate was secured, the B-series block was ready to be placed in the Sunnen SV-10 cylinder hone. During the honing process, diamond abrasives and CBN (cubic boron nitride) abrasives were used to rough the cylinder to a round and taper-free bore. One big advantage of diamond- or CBN-based abrasives (second in hardness only to synthetic diamonds) is that they wear very little. Since these hard materials keep their shape very well, it’s the perfect abrasive to remove taper and out-of-roundness from the cylinder. Unfortunately, diamonds and CBN are not ideal for the final finish of a cylinder bore. Instead, conventional silicon carbide-based stones are used for a superior finish. Which abrasives to use depend on a number of factors including the type of material to be honed and its relative hardness.

[pullquote]OUR AVERAGE VALUES… ARE CONSIDERED IDEAL FOR… A B-SERIES ENGINE[/pullquote]For this B-series engine equipped with the RS Machine sleeves that had already been run for about a year, we found that the Sunnen P28NM55 CBN-based abrasives were the best for the roughing process. Since there was major taper and distortion in the bores (likely because a torque plate wasn’t used when the engine block was previously sleeved and machined), the 220-grit CBN abrasives were a good choice. Once we got to about 0.003″ to a final desired bore size, we switched to the JHU623 silicon-carbide 280-grit stones. These stones cut about 0.002″ out of the bores and then surface checking began. At this stage, our goal was to cut the oil retaining valleys into the cylinders. Once we were happy with the numbers coming up on the profilometer, we continued until we were at the final desired bore size. Then anywhere from four-to-eight light pressure strokes were made with the C30C05 600-grit finishing stones to achieve the final numbers. Our average RvK values were at 30, with the Rk value coming in at 25. These are what would be considered ideal for long cylinder life and proper oil retention on a B-series engine. Low-break in friction was also evident with RpK measurements of around 8. While plateau honing to specific target RvK and Rk values triples the honing process time, recording and blueprinting these specifications allows for fine tuning of future machining operations.